ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 18, 2025 07:10 Back to list

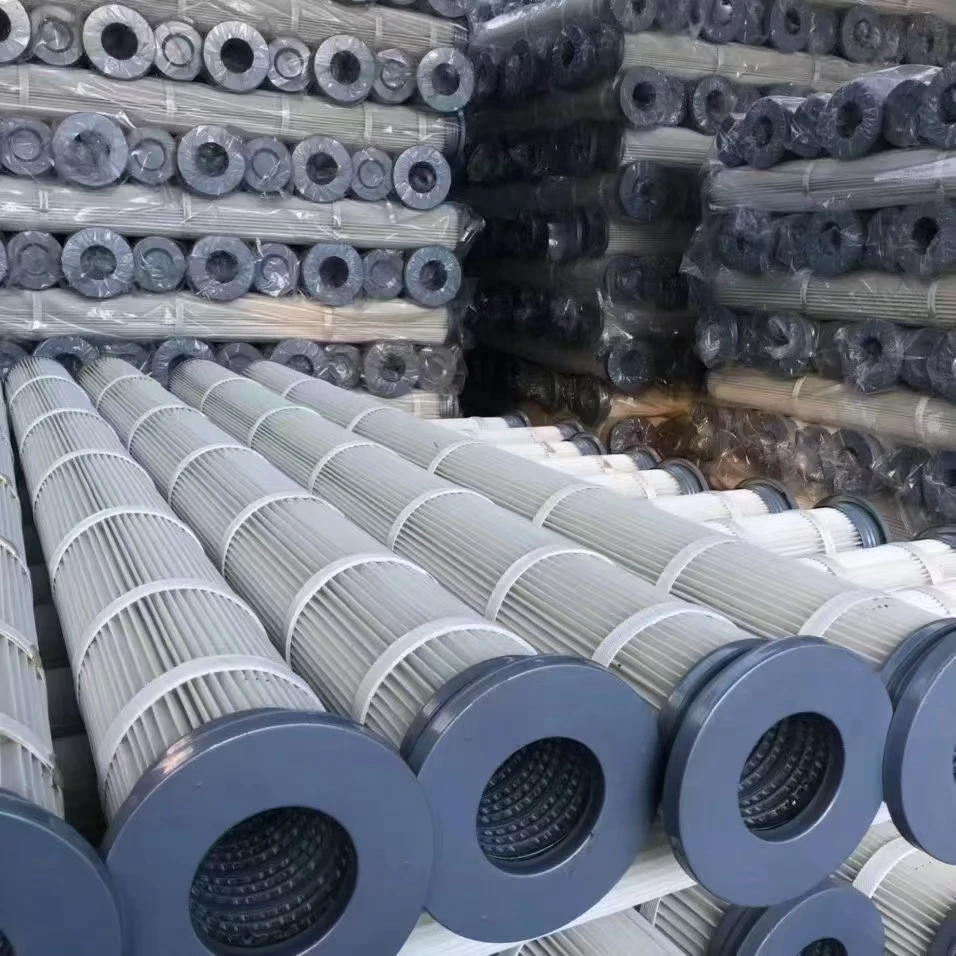

dust extractor pleated filter cartridges

Dust extractor filter cartridges stand as a pivotal component in maintaining air quality and ensuring the smooth operation of equipment within industrial environments. With decades of technological evolution, their importance has only grown with the increasing focus on workplace safety and environmental standards.

Moreover, the correct maintenance and frequent replacement of these filter cartridges is essential for sustained equipment performance. Clogged or worn filters can lead to engine strain, decreased airflow, and eventually equipment failure, leading to costly downtimes. Therefore, understanding the life expectancy of your filter cartridges based on your operational environment's specific dust generation is key for scheduling replacements. The expertise required to select and maintain dust extractor filter cartridges extends beyond the basic understanding of their specifications. It requires an authoritative grasp over the interaction of dust particle types - such as metallic dust, wood particulate, or chemical residues – with various filtration technologies. Engaging with industrial hygiene experts or consulting with filtration technology specialists can provide valuable insights, ensuring your choice of filter cartridge not only protects the equipment but significantly lowers health risks for employees. Trust plays a significant role in this process. Opting for manufacturers with a reputation for high-quality standards and a proven track record in filter technology can mitigate risks associated with substandard materials or misleading efficiency claims. Leading providers often offer valuable post-sale support, including installation guides, maintenance kits, and professional advice, reinforcing their commitment to customer success and safety. In conclusion, dust extractor filter cartridges are indispensable components that serve as frontline defenses against hazardous air quality in industrial environments. Their selection should be informed by a comprehensive understanding of the operational environment, regulatory requirements, and technological advancements in filtration. By leveraging expertise and fostering relationships with reputable manufacturers, businesses can ensure not only compliance but also the well-being of their workers and the longevity of their machinery. Investing in high-quality dust extractor filter cartridges isn't merely an operational necessity—it's a commitment to fostering safer, more productive workplaces.

Moreover, the correct maintenance and frequent replacement of these filter cartridges is essential for sustained equipment performance. Clogged or worn filters can lead to engine strain, decreased airflow, and eventually equipment failure, leading to costly downtimes. Therefore, understanding the life expectancy of your filter cartridges based on your operational environment's specific dust generation is key for scheduling replacements. The expertise required to select and maintain dust extractor filter cartridges extends beyond the basic understanding of their specifications. It requires an authoritative grasp over the interaction of dust particle types - such as metallic dust, wood particulate, or chemical residues – with various filtration technologies. Engaging with industrial hygiene experts or consulting with filtration technology specialists can provide valuable insights, ensuring your choice of filter cartridge not only protects the equipment but significantly lowers health risks for employees. Trust plays a significant role in this process. Opting for manufacturers with a reputation for high-quality standards and a proven track record in filter technology can mitigate risks associated with substandard materials or misleading efficiency claims. Leading providers often offer valuable post-sale support, including installation guides, maintenance kits, and professional advice, reinforcing their commitment to customer success and safety. In conclusion, dust extractor filter cartridges are indispensable components that serve as frontline defenses against hazardous air quality in industrial environments. Their selection should be informed by a comprehensive understanding of the operational environment, regulatory requirements, and technological advancements in filtration. By leveraging expertise and fostering relationships with reputable manufacturers, businesses can ensure not only compliance but also the well-being of their workers and the longevity of their machinery. Investing in high-quality dust extractor filter cartridges isn't merely an operational necessity—it's a commitment to fostering safer, more productive workplaces.

Next:

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: