ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 20, 2025 10:07 Back to list

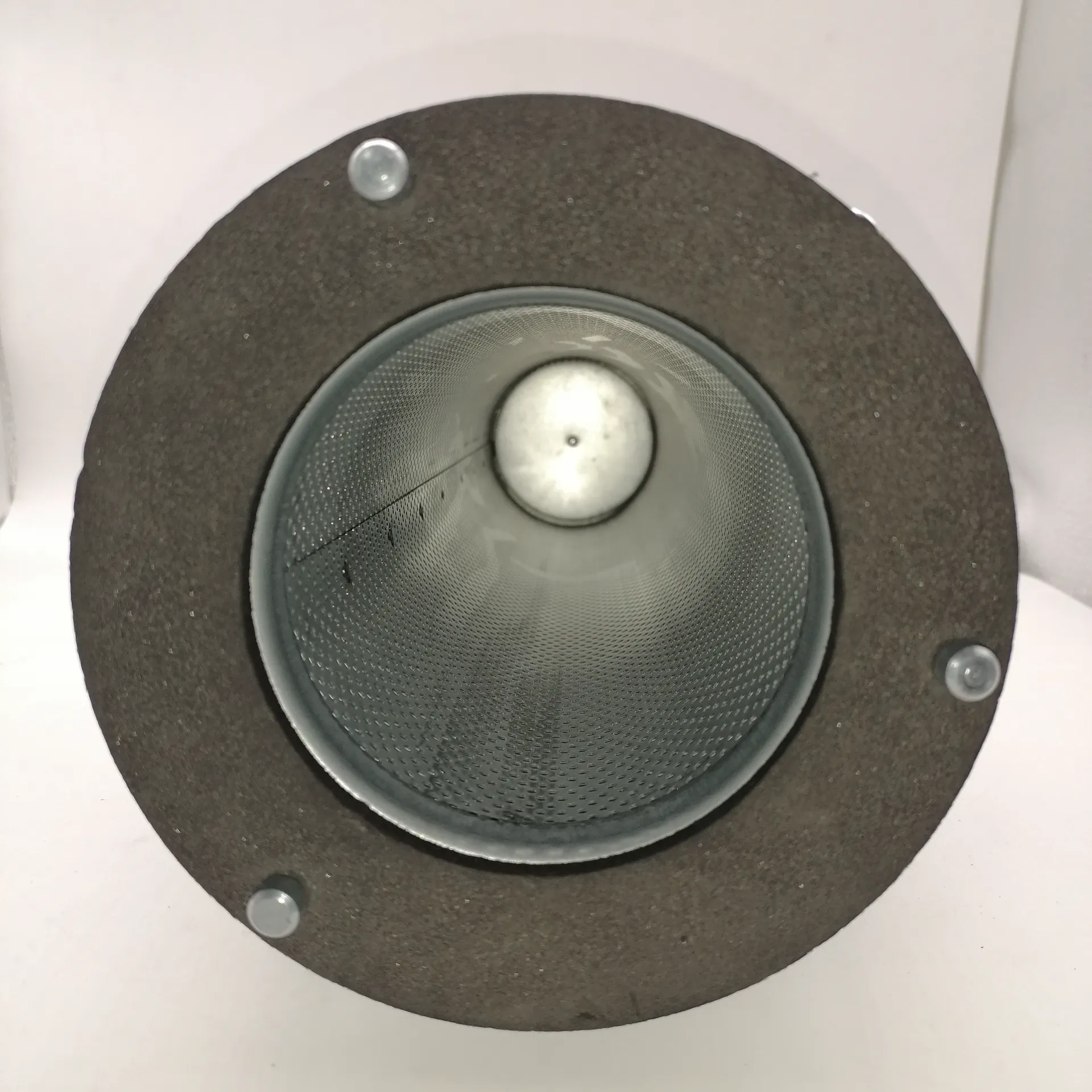

industrial dust collector cartridge filters dust extractor pleated filter cartridges

In the realm of industrial cleaning and air quality management, selecting the right dust extractor filter cartridge is crucial for efficiency and safety. This component plays a pivotal role in maintaining a clean working environment, ensuring longevity of equipment, and protecting human health from hazardous airborne particles. Understanding the nuances of filter cartridges provides an edge in optimizing industrial operations.

Filter maintenance also significantly influences their effectiveness and lifespan. Regular inspection schedules, guided by the manufacturer's recommendations and operational hours, prevent unexpected downtimes. Implementing a proactive maintenance program that includes periodic cleaning and timely replacements ensures consistent extractor performance. Employing a differential pressure gauge to monitor filter status is a reliable method for real-time assessment, signaling when replacements are necessary based on actual conditions rather than preset timelines. Innovations in filter design have also introduced options like self-cleaning systems, which integrate pulse-jet cleaning mechanisms that dislodge accumulated dust without the need for manual intervention. This technology serves as a boon for industries with continuous operations, minimizing interruptions and enhancing productivity. Additionally, selecting filters with anti-static properties is essential in environments where static electricity poses a risk, further illustrating the importance of context-specific filter features. Moreover, the authoritative aspect of filter selection encompasses compliance with industry standards and regulations. Ensuring that filter cartridges meet OSHA, EPA, and other relevant health and safety standards is non-negotiable. By adhering to these regulations, industries not only safeguard their workforce but also avoid potential legal and financial repercussions. The trustworthiness of a supplier is validated through these certifications, reflecting their commitment to quality and safety. In conclusion, the expertise in selecting an optimal dust extractor filter cartridge combines a thorough understanding of material science, environmental considerations, and regulatory compliance. Partnering with reputable suppliers who offer comprehensive support and guidance in choosing and maintaining filters can transform routine industrial hygiene into a strategic advantage. Ultimately, this commitment to air quality is an investment in sustainable industrial practice, ensuring operational excellence and the well-being of employees.

Filter maintenance also significantly influences their effectiveness and lifespan. Regular inspection schedules, guided by the manufacturer's recommendations and operational hours, prevent unexpected downtimes. Implementing a proactive maintenance program that includes periodic cleaning and timely replacements ensures consistent extractor performance. Employing a differential pressure gauge to monitor filter status is a reliable method for real-time assessment, signaling when replacements are necessary based on actual conditions rather than preset timelines. Innovations in filter design have also introduced options like self-cleaning systems, which integrate pulse-jet cleaning mechanisms that dislodge accumulated dust without the need for manual intervention. This technology serves as a boon for industries with continuous operations, minimizing interruptions and enhancing productivity. Additionally, selecting filters with anti-static properties is essential in environments where static electricity poses a risk, further illustrating the importance of context-specific filter features. Moreover, the authoritative aspect of filter selection encompasses compliance with industry standards and regulations. Ensuring that filter cartridges meet OSHA, EPA, and other relevant health and safety standards is non-negotiable. By adhering to these regulations, industries not only safeguard their workforce but also avoid potential legal and financial repercussions. The trustworthiness of a supplier is validated through these certifications, reflecting their commitment to quality and safety. In conclusion, the expertise in selecting an optimal dust extractor filter cartridge combines a thorough understanding of material science, environmental considerations, and regulatory compliance. Partnering with reputable suppliers who offer comprehensive support and guidance in choosing and maintaining filters can transform routine industrial hygiene into a strategic advantage. Ultimately, this commitment to air quality is an investment in sustainable industrial practice, ensuring operational excellence and the well-being of employees.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: