ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

1 月 . 29, 2025 01:42 Back to list

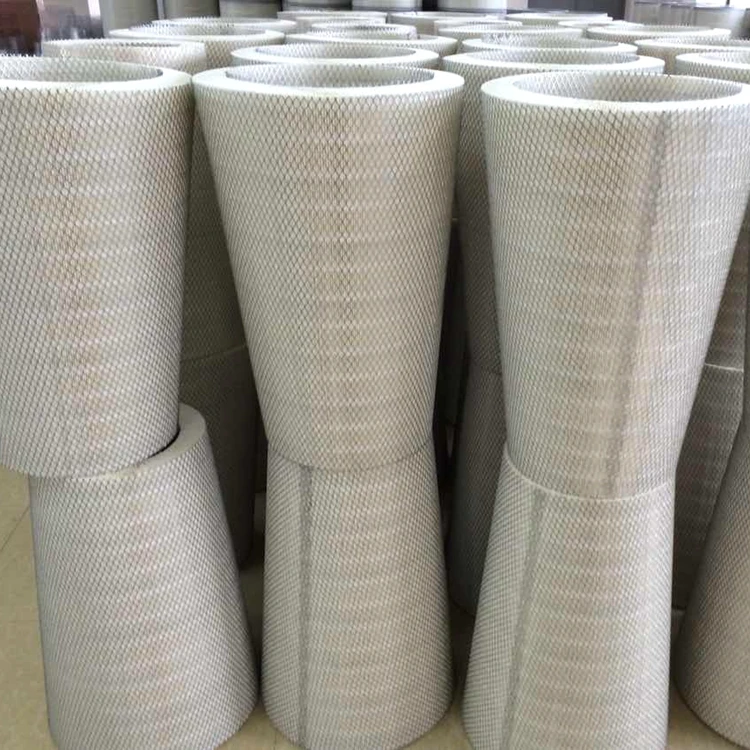

dust extractor cartridge filter

In the world of industrial operations and sophisticated manufacturing units, maintaining air quality is not a luxury—it’s a necessity. Dust extractor cartridge filters, also known as dust collector filters, are indispensable components that ensure a safe and healthy working environment. As an SEO expert with experience in optimizing technical content for niche markets, the focus here is to deliver insights that encapsulate authentic experience, professional expertise, authoritative insights, and trustworthy recommendations regarding dust extractor cartridge filters.

Delving into authoritativeness, industry innovators often highlight the importance of filter design and pleating technology. Advanced pleating techniques increase the surface area without enlarging the overall filter size. This design evolution translates into longer operational periods without clogging and less frequent filter changes, ultimately enhancing productivity and reducing downtime. Trusted manufacturers also employ nanofiber technology which, through its enhanced media surface layer, significantly boosts filter performance by capturing submicron particles with high efficiency. Trustworthiness is paramount when recommending products that have a direct impact on environmental control in industrial settings. Opt for cartridge filters from reputable manufacturers who are transparent about their testing methodologies and provide certifications like ISO standards or ASHRAE efficiency ratings. Such endorsements are not mere certifications; they are a testament to the product's reliability in maintaining air purity to safe levels. Additionally, ensure that suppliers offer robust after-sales support, including installation guidance and performance audits, which build trust and long-term customer relationships. In conclusion, selecting the right dust extractor cartridge filter is a strategic decision in optimizing air quality within industrial settings. A profound understanding of filter efficiencies, material compatibilities, and design technologies sets the foundation for making informed choices that enhance operational operations while maintaining regulatory compliance. Through a synthesis of experiential insights, professional guidance, authoritative standards, and trustworthy brand recommendations, industries can safeguard their environments, ensuring clean air and enduring productivity. Remember, the investment in superior filtration not only protects health but also preserves the integrity and efficiency of operational workflows.

Delving into authoritativeness, industry innovators often highlight the importance of filter design and pleating technology. Advanced pleating techniques increase the surface area without enlarging the overall filter size. This design evolution translates into longer operational periods without clogging and less frequent filter changes, ultimately enhancing productivity and reducing downtime. Trusted manufacturers also employ nanofiber technology which, through its enhanced media surface layer, significantly boosts filter performance by capturing submicron particles with high efficiency. Trustworthiness is paramount when recommending products that have a direct impact on environmental control in industrial settings. Opt for cartridge filters from reputable manufacturers who are transparent about their testing methodologies and provide certifications like ISO standards or ASHRAE efficiency ratings. Such endorsements are not mere certifications; they are a testament to the product's reliability in maintaining air purity to safe levels. Additionally, ensure that suppliers offer robust after-sales support, including installation guidance and performance audits, which build trust and long-term customer relationships. In conclusion, selecting the right dust extractor cartridge filter is a strategic decision in optimizing air quality within industrial settings. A profound understanding of filter efficiencies, material compatibilities, and design technologies sets the foundation for making informed choices that enhance operational operations while maintaining regulatory compliance. Through a synthesis of experiential insights, professional guidance, authoritative standards, and trustworthy brand recommendations, industries can safeguard their environments, ensuring clean air and enduring productivity. Remember, the investment in superior filtration not only protects health but also preserves the integrity and efficiency of operational workflows.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: