Tel:

+8618931101301

Tel:

+8618931101301

10 月 . 10, 2024 22:41 Back to list

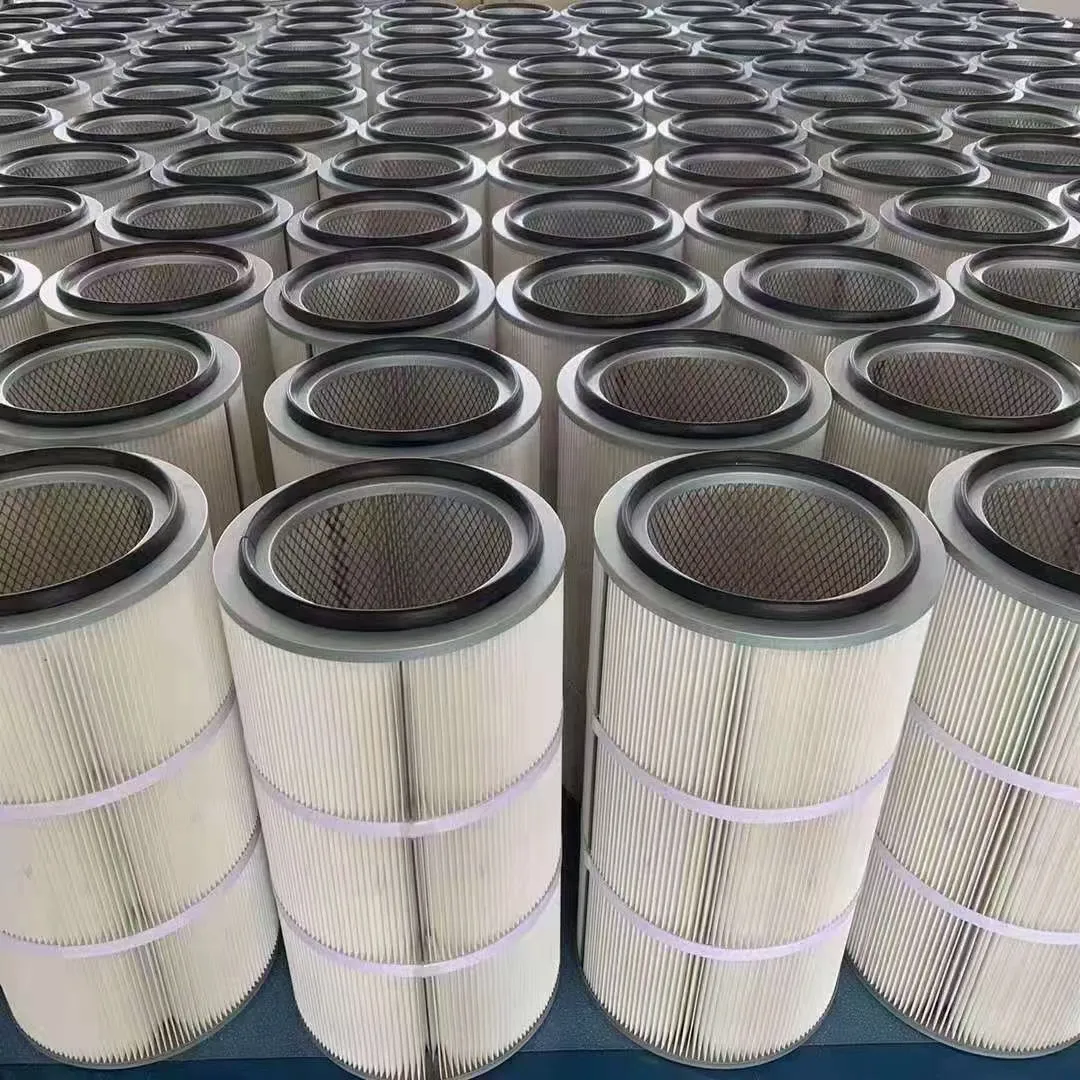

Effective Dust Extractor Cartridge Filters for Optimal Air Quality and Performance

The Importance of Dust Extractor Cartridge Filters in Industrial Applications

In the realm of industrial operations, maintaining a clean and safe working environment is paramount. One of the most effective solutions for controlling airborne dust is the implementation of dust extractor cartridge filters. These specialized filters play a crucial role in ensuring air quality and compliance with health and safety regulations, thereby safeguarding both workers and machinery.

What are Dust Extractor Cartridge Filters?

Dust extractor cartridge filters are advanced filtration systems designed to collect and remove airborne particulate matter generated during various industrial processes. These systems are typically integrated into dust collection systems and work by drawing in contaminated air and passing it through a series of filter cartridges. The cartridges trap dust particles, preventing them from re-entering the workspace.

The design of these filters allows for high filtration efficiency, meaning they can capture even very fine particles, such as those that measure 0.5 microns or smaller. This level of efficiency is critical in industries such as woodworking, metal fabrication, pharmaceuticals, and food processing, where airborne contaminants can pose significant hazards.

Benefits of Using Cartridge Filters

1. Enhanced Air Quality The primary benefit of using dust extractor cartridge filters is the significant improvement in air quality. By effectively trapping dust and other particulate matter, these filters help create a healthier work environment, reducing the risk of respiratory issues for employees.

2. Increased Productivity Clean air translates to better working conditions, which can lead to improved employee productivity. Workers can focus on their tasks without the distraction of dust and allergens in the air.

dust extractor cartridge filter

3. Protection of Equipment Dust and particulates can accumulate on machinery and equipment, leading to increased wear and tear and potential breakdowns. By utilizing cartridge filters, industries can protect their investments and reduce downtime caused by maintenance and repairs.

4. Regulatory Compliance Many industries are subject to strict regulations regarding air quality and employee safety. Implementing effective dust extraction systems with cartridge filters helps organizations comply with these regulations, avoiding potential fines and legal issues.

5. Cost-Effectiveness Cartridge filters can be a cost-effective solution for dust management. Although the initial investment may seem significant, the long-term savings associated with reduced maintenance costs, improved worker health, and enhanced productivity can outweigh the initial expense.

Choosing the Right Cartridge Filter

Selecting the appropriate dust extractor cartridge filter requires careful consideration of several factors, including the type of dust being generated, the volume of air needing filtration, and specific industry requirements. Filters come in various media types, such as polyester, cellulose, and fiberglass, each offering different filtration efficiencies and durability levels.

It's also essential to consider the filter's capacity and the maintenance requirements involved. Regular maintenance, including cleaning or replacing filters, is vital for ensuring optimal performance and extending the lifespan of the filtration system.

Conclusion

In conclusion, dust extractor cartridge filters are an indispensable component of modern industrial operations. They play a vital role in improving air quality, protecting both workers and equipment, ensuring regulatory compliance, and enhancing overall productivity. Organizations seeking to create a safer working environment would be well-served by investing in these advanced filtration systems. By doing so, they not only prioritize the health and well-being of their employees but also contribute to a more sustainable and efficient workplace. As industries continue to evolve, the importance of effective dust extraction solutions like cartridge filters will only grow, making them an essential element in the responsible management of air quality in industrial settings.

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Email:

Email: