ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 13, 2025 13:07 Back to list

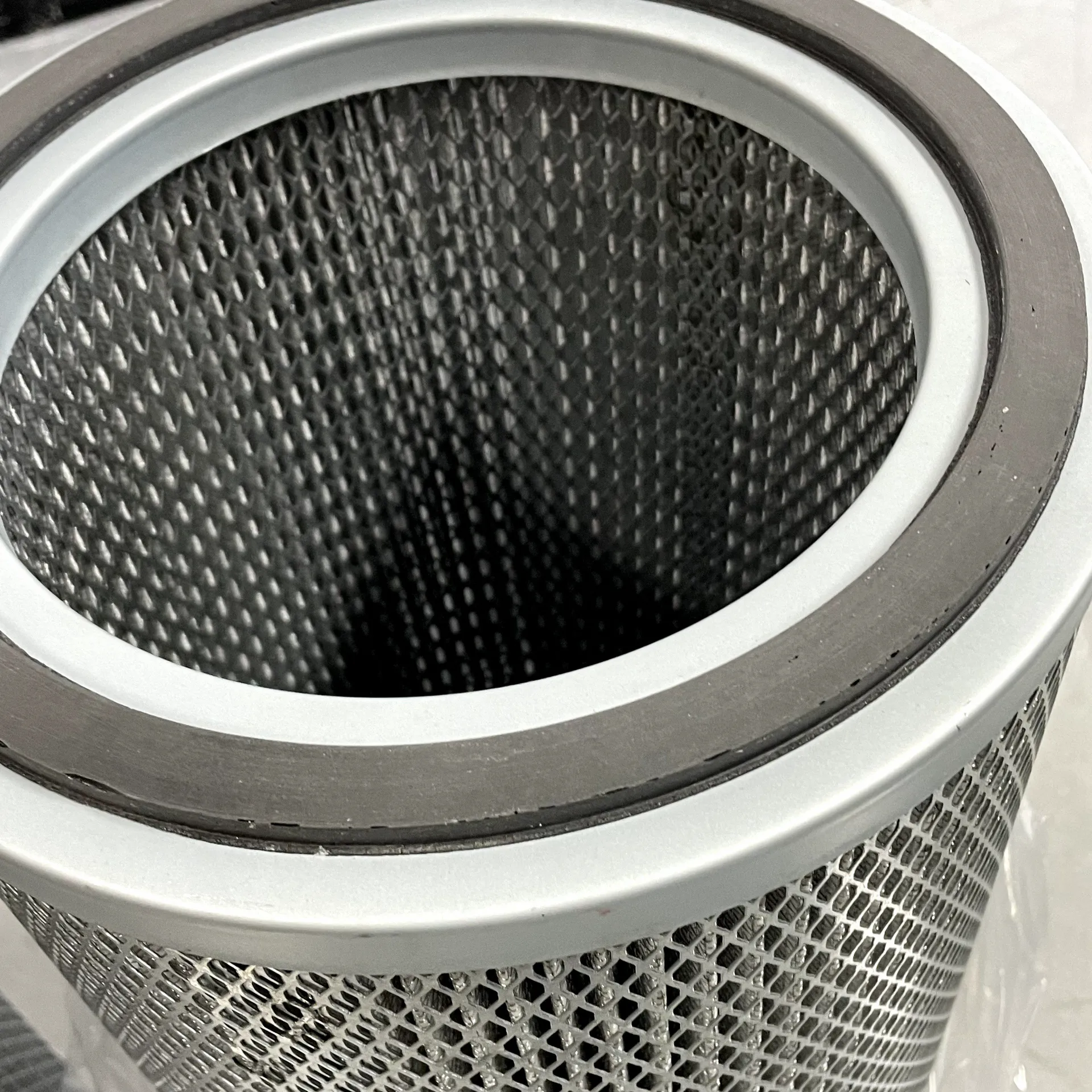

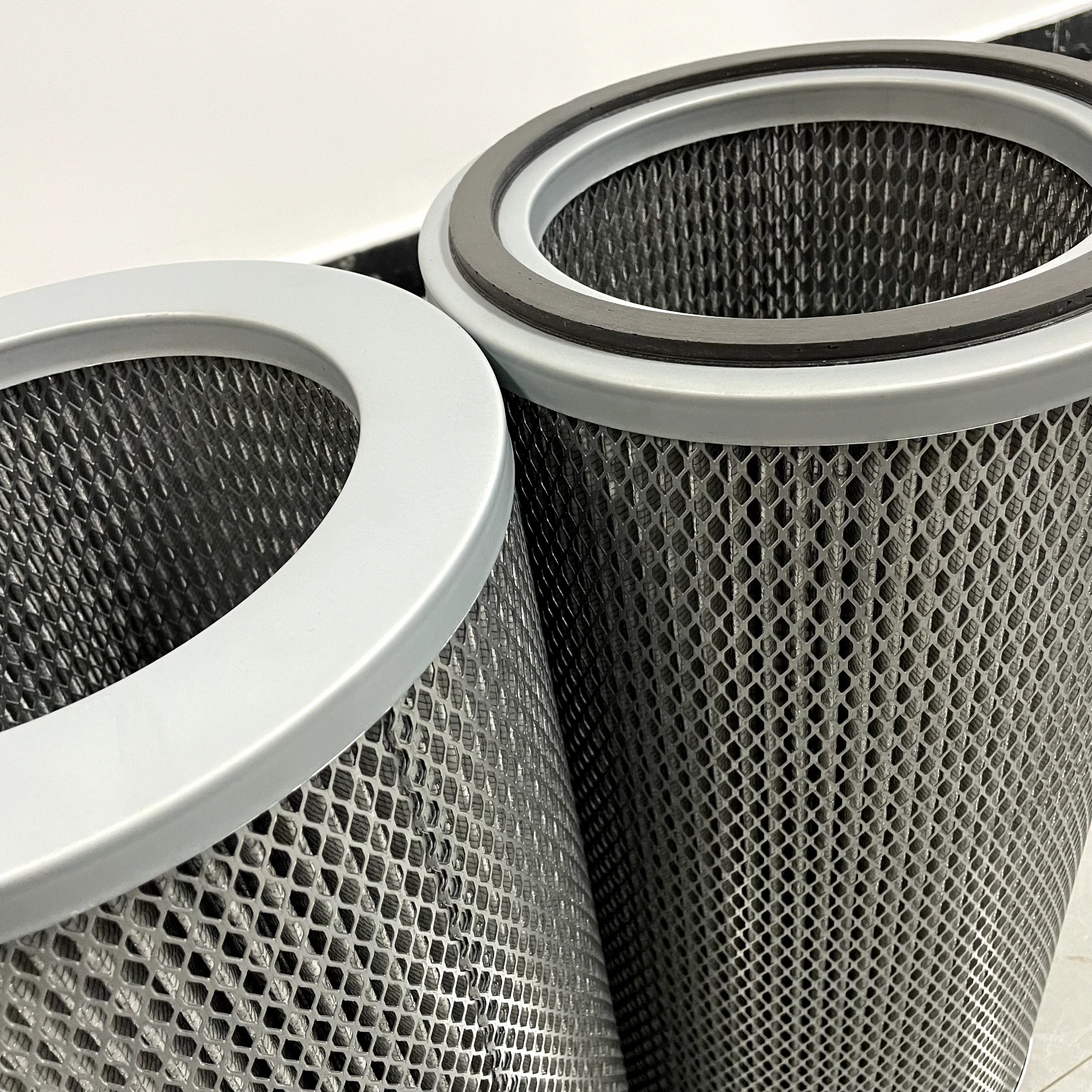

dust collector filter cartridge manufacturers

Dust collector cartridge filters have become an integral component in various industries that prioritize maintaining air quality and ensuring safety within their operations. As industrial emissions regulations become increasingly stringent, the demand for high-performance dust collector systems has surged. These filters not only enhance operational efficiency but also safeguard workers’ health by capturing harmful particles. Here is a thorough examination of dust collector cartridge filters, emphasizing experience, expertise, authoritativeness, and trustworthiness.

Authoritativeness in dust collector cartridge filters is bolstered by endorsements and certifications from regulatory bodies and industry standards organizations. For instance, filters certified by the Occupational Safety and Health Administration (OSHA) or bearing the CE mark provide users confidence in their efficacy and safety. These accreditations confirm that the filters meet or exceed the prescribed safety and performance criteria, granting them a respected status in the industrial sector. Trustworthiness comes from both empirical performance and peer recommendations. Businesses that have adopted these filters report significant improvements in air quality and employee well-being, underlining their reliability. Moreover, user testimonials and case studies frequently highlight the filters' high efficiency, ease of maintenance, and cost-effectiveness—critical aspects for stakeholders seeking return on investment and sustainable operation. In conclusion, dust collector cartridge filters exemplify an amalgamation of experience, expertise, authoritativeness, and trustworthiness. They stand as a testament to modern engineering prowess, providing solutions that address complex industrial challenges with precision. As industries continue to evolve, these filters will likely play an even more pivotal role in fostering safer, cleaner, and more efficient work environments. Choosing the right dust collector cartridge filter, validated by expert recommendations and authoritative certifications, positions companies to achieve not only compliance but also operational excellence.

Authoritativeness in dust collector cartridge filters is bolstered by endorsements and certifications from regulatory bodies and industry standards organizations. For instance, filters certified by the Occupational Safety and Health Administration (OSHA) or bearing the CE mark provide users confidence in their efficacy and safety. These accreditations confirm that the filters meet or exceed the prescribed safety and performance criteria, granting them a respected status in the industrial sector. Trustworthiness comes from both empirical performance and peer recommendations. Businesses that have adopted these filters report significant improvements in air quality and employee well-being, underlining their reliability. Moreover, user testimonials and case studies frequently highlight the filters' high efficiency, ease of maintenance, and cost-effectiveness—critical aspects for stakeholders seeking return on investment and sustainable operation. In conclusion, dust collector cartridge filters exemplify an amalgamation of experience, expertise, authoritativeness, and trustworthiness. They stand as a testament to modern engineering prowess, providing solutions that address complex industrial challenges with precision. As industries continue to evolve, these filters will likely play an even more pivotal role in fostering safer, cleaner, and more efficient work environments. Choosing the right dust collector cartridge filter, validated by expert recommendations and authoritative certifications, positions companies to achieve not only compliance but also operational excellence.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: