ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 14, 2025 21:44 Back to list

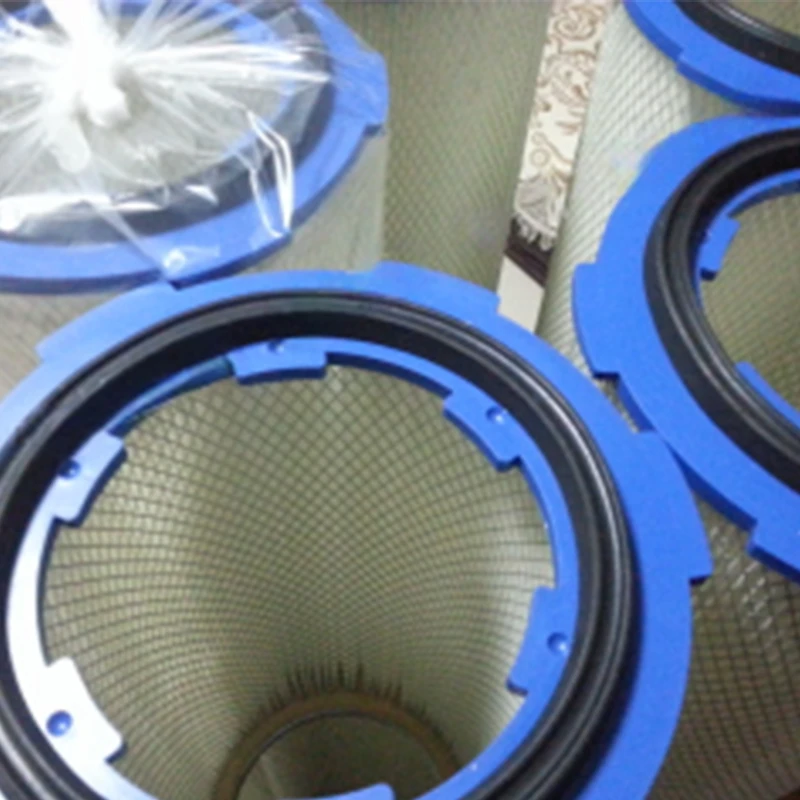

industrial dust collector cartridge filters dust extractor pleated filter cartridges

Dust cartridges, a crucial component in modern industrial operations, have been gaining attention for their unmatched efficiency in improving air quality across various sectors. As industries seek to meet stringent environmental standards and ensure the safety of their workforce, the demand for high-quality dust cartridges continues to rise. This article explores the core attributes that make dust cartridges indispensable, supported by expert insights and real-world applications.

Authority in the field of dust cartridge manufacturing is established through stringent testing and quality assurance. Reputable manufacturers subject their products to rigorous efficiency tests such as the ASHRAE 52.2 or EN 779 standards, ensuring they meet or exceed industry benchmarks. Trust is cultivated by transparent communication of test results and certifications, an approach advocated by filtration quality auditor Sarah Lin. When manufacturers disclose comprehensive testing data, it allows buyers to make informed decisions, she asserts, reinforcing the trust component in product selection. Moreover, trustworthiness is further enhanced by real-time performance monitoring technologies embedded within advanced dust cartridges. These sensors provide data on filter efficiency and lifespan, allowing industries to perform predictive maintenance and avoid unexpected operational downtimes. Real-time monitoring tech has transformed our plant maintenance schedule, minimizing production halts, remarks Dennis Trent, a plant manager in a chemical manufacturing firm. In conclusion, the significance of dust cartridges extends beyond mere air filtration; they represent a fusion of experience, expertise, authority, and trustworthiness. The continuous innovation and application of technology in their design and monitoring ensure that they remain pivotal in achieving operational efficiency and safeguarding health standards across industries. As research progresses and regulatory demands evolve, the role of dust cartridges will undoubtedly expand, shaping the future of industrial air quality management.

Authority in the field of dust cartridge manufacturing is established through stringent testing and quality assurance. Reputable manufacturers subject their products to rigorous efficiency tests such as the ASHRAE 52.2 or EN 779 standards, ensuring they meet or exceed industry benchmarks. Trust is cultivated by transparent communication of test results and certifications, an approach advocated by filtration quality auditor Sarah Lin. When manufacturers disclose comprehensive testing data, it allows buyers to make informed decisions, she asserts, reinforcing the trust component in product selection. Moreover, trustworthiness is further enhanced by real-time performance monitoring technologies embedded within advanced dust cartridges. These sensors provide data on filter efficiency and lifespan, allowing industries to perform predictive maintenance and avoid unexpected operational downtimes. Real-time monitoring tech has transformed our plant maintenance schedule, minimizing production halts, remarks Dennis Trent, a plant manager in a chemical manufacturing firm. In conclusion, the significance of dust cartridges extends beyond mere air filtration; they represent a fusion of experience, expertise, authority, and trustworthiness. The continuous innovation and application of technology in their design and monitoring ensure that they remain pivotal in achieving operational efficiency and safeguarding health standards across industries. As research progresses and regulatory demands evolve, the role of dust cartridges will undoubtedly expand, shaping the future of industrial air quality management.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: