ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 02, 2025 03:45 Back to list

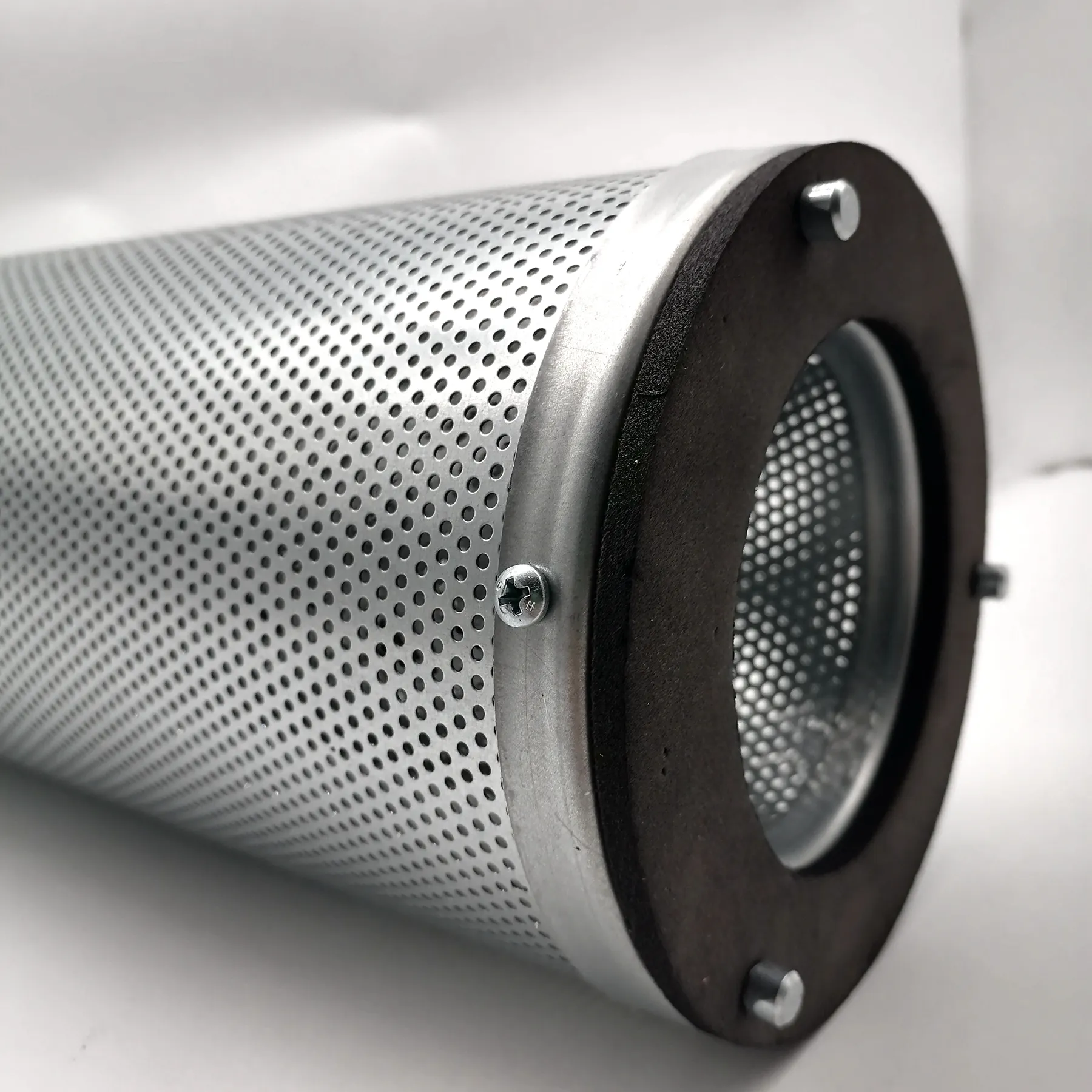

dust cartridge filter

Dust cartridge filters are a critical component in many industrial applications, playing a pivotal role in maintaining air quality and ensuring the efficient operation of machinery. With the increasing demand for clean air solutions and stringent environmental regulations, understanding the intricacies of these filters not only enhances operational efficiency but also contributes to a healthier workplace environment.

Authoritativeness in the domain of dust cartridge filters is often established through compliance with industry standards and certifications. Filters that meet standards such as ISO and ASHRAE provide an assurance of quality and performance, both crucial for industries that cannot afford downtime or compromised air quality. Expert manufacturers who have earned a reputation for their adherence to these standards deliver not only a product but also peace of mind to their clients. Trustworthiness is demonstrated through proven performance in field applications and positive testimonials from industry practitioners. Companies that invest in rigorous testing and validation processes, and that offer robust after-sales support, reinforce their credibility in the market. Real-world success stories showcase how dust cartridge filters have revolutionized air quality management in various industries, from manufacturing plants to power generation facilities. These stories often highlight significant improvements in air quality and corresponding health benefits to workers, increasing the value proposition of investing in high-quality filtration solutions. Considering these elements, it’s clear that dust cartridge filters are more than just an accessory; they are a vital component of industrial operations. Selecting the right filter can lead to enhanced operational efficiency, compliance with safety standards, and reduced environmental impact. Prospective buyers are advised to engage with experienced manufacturers who can offer tailored solutions and provide guidance based on specific industrial needs and challenges. In essence, a strategic approach to dust cartridge filter selection involves understanding the operational context, evaluating the quality and credentials of the filter, and fostering relationships with reputable suppliers. Such diligence not only optimizes industrial operations but also contributes to stakeholder trust and sustainability in an increasingly environmentally conscious market.

Authoritativeness in the domain of dust cartridge filters is often established through compliance with industry standards and certifications. Filters that meet standards such as ISO and ASHRAE provide an assurance of quality and performance, both crucial for industries that cannot afford downtime or compromised air quality. Expert manufacturers who have earned a reputation for their adherence to these standards deliver not only a product but also peace of mind to their clients. Trustworthiness is demonstrated through proven performance in field applications and positive testimonials from industry practitioners. Companies that invest in rigorous testing and validation processes, and that offer robust after-sales support, reinforce their credibility in the market. Real-world success stories showcase how dust cartridge filters have revolutionized air quality management in various industries, from manufacturing plants to power generation facilities. These stories often highlight significant improvements in air quality and corresponding health benefits to workers, increasing the value proposition of investing in high-quality filtration solutions. Considering these elements, it’s clear that dust cartridge filters are more than just an accessory; they are a vital component of industrial operations. Selecting the right filter can lead to enhanced operational efficiency, compliance with safety standards, and reduced environmental impact. Prospective buyers are advised to engage with experienced manufacturers who can offer tailored solutions and provide guidance based on specific industrial needs and challenges. In essence, a strategic approach to dust cartridge filter selection involves understanding the operational context, evaluating the quality and credentials of the filter, and fostering relationships with reputable suppliers. Such diligence not only optimizes industrial operations but also contributes to stakeholder trust and sustainability in an increasingly environmentally conscious market.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: