Tel:

+8618931101301

Tel:

+8618931101301

12 月 . 03, 2024 17:31 Back to list

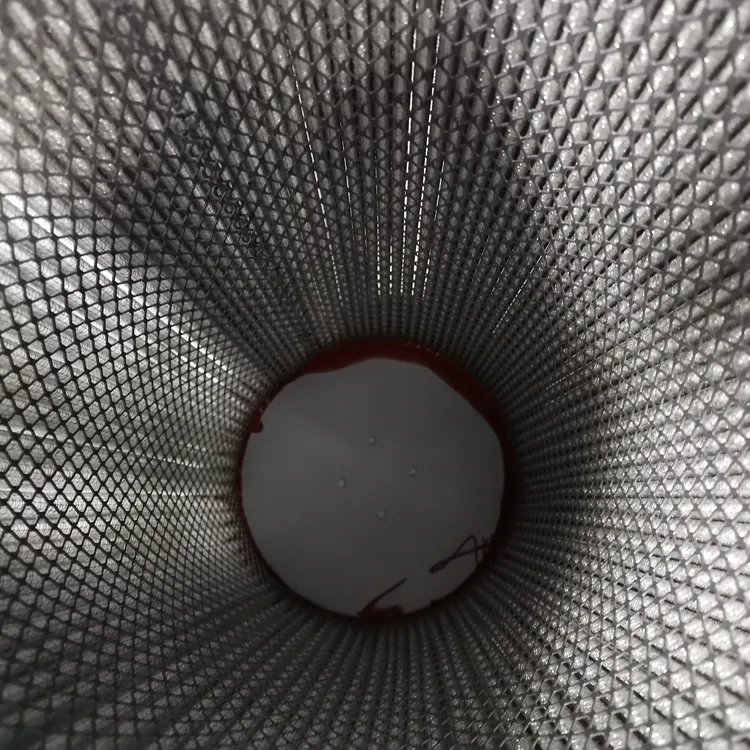

drilling rig air filter

The Importance of Air Filters in Drilling Rigs

Air filters play a crucial role in the operation and maintenance of drilling rigs, especially in environments that are often dusty and laden with contaminants. Proper filtration not only ensures the efficiency of the equipment but also contributes to the safety and health of personnel on-site. In this article, we will explore the types of air filters used in drilling rigs, their benefits, maintenance considerations, and best practices for maximizing their effectiveness.

Types of Air Filters

Drilling rigs typically utilize several types of air filters to protect both machinery and workers from harmful particulates. The most common types include 1. Pre-Filter This is the first line of defense against larger particles. Pre-filters are designed to capture dust, dirt, and other significant contaminants before they reach the primary filters. They are often washable and reusable, which makes them economically viable. 2. HEPA Filter High-Efficiency Particulate Air (HEPA) filters offer a higher level of filtration, capable of trapping 99.97% of particles that are 0.3 microns in size or larger, including aerosols and allergens. These filters are essential in environments where respiratory safety is a concern.

3. Activated Carbon Filter Used primarily for gas and odor removal, activated carbon filters can absorb volatile organic compounds (VOCs) and other harmful chemicals that may be present in the air on drilling sites.

4. Chemical Filters In certain drilling operations, especially those involving hazardous materials, chemical filters may be necessary to neutralize specific toxic gases that can harm workers' health.

Benefits of Air Filters

The inclusion of air filters in drilling rigs offers multiple advantages - Enhanced Worker Safety Air filters help reduce the inhalation of harmful particulates and gases, thereby protecting the health of workers on-site. This is especially critical in remote areas where access to immediate medical assistance may be limited. - Increased Equipment Longevity Clean air is essential for the proper functioning of machinery. Contaminants can lead to increased wear and tear on engine components. Regular replacement of air filters can significantly extend the lifespan of drilling equipment.

- Improved Operational Efficiency Clean filters can enhance the overall performance of drilling rigs. Clogged or dirty filters can restrict airflow, resulting in reduced engine power and efficiency. By ensuring that air filters are regularly maintained and replaced, operations can run smoothly and efficiently.

- Compliance with Regulations Many drilling operations are subject to environmental and safety regulations that necessitate proper air filtration systems. Using and maintaining effective air filters can help companies avoid fines and ensure compliance with industry standards.

drilling rig air filter

Maintenance Considerations

Proper maintenance of air filters is vital to maximize their effectiveness. Here are several key considerations - Regular Inspections Air filters should be inspected regularly for signs of wear or clogging. Depending on the environment, filters may need to be checked weekly or monthly.

- Prompt Replacement Filters should be replaced according to manufacturer recommendations or when performance is noticeably diminished. Ignoring this can lead to engine strain and an increased risk of failure.

- Cleaning Procedures Depending on the type of filter, some may be washable and reusable. Proper cleaning procedures should be followed to avoid damaging these filters and ensure they are functioning effectively.

- Training and Awareness Training personnel on the importance of air filtration and how to identify filter issues can significantly improve maintenance practices and safety on site.

Best Practices

To achieve optimal performance from air filters in drilling rigs, several best practices can be implemented - Choose Quality Filters Invest in high-quality filters that are appropriate for the specific working conditions of the drilling site.

- Monitor Air Quality Regularly monitoring air quality can help identify when filters may need replacement or maintenance before issues become severe.

- Document Maintenance Keep thorough records of filter replacement dates, inspections, and maintenance activities to ensure compliance and facilitate planning.

In summary, air filters are an indispensable component of drilling rigs, ensuring the safety of personnel and the longevity and efficiency of the equipment. By understanding the different types of filters available, recognizing their importance, and implementing proper maintenance practices, drilling operations can optimize performance while safeguarding the health of their workforce.

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Email:

Email: