ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

1 月 . 28, 2025 01:00 Back to list

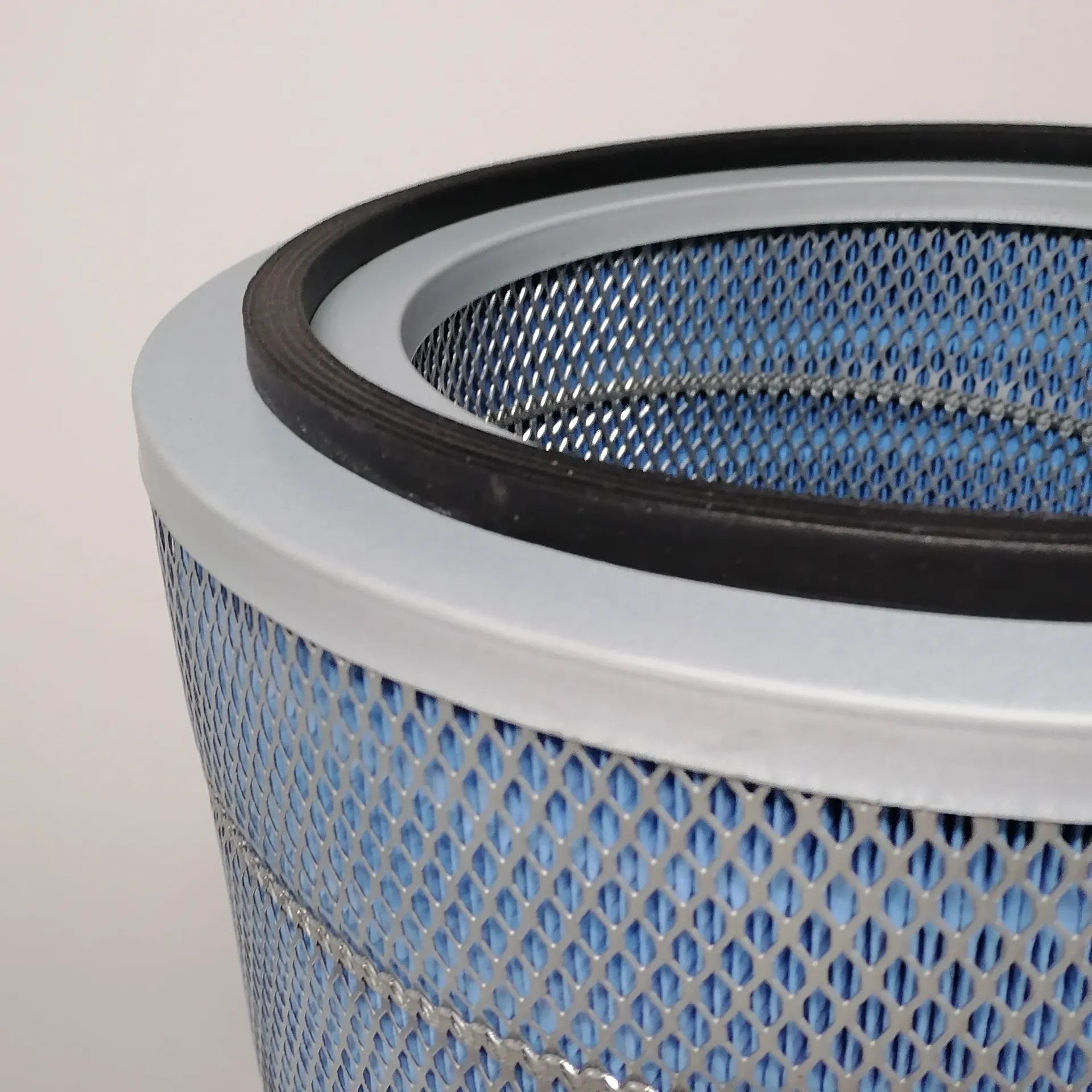

drilling rig air filter

Selecting the right air filter for a drilling rig isn't just a matter of efficiency; it's a crucial aspect affecting the longevity and productivity of the entire operation. A drilling rig air filter acts as the heart of the system, ensuring that dirt, debris, and contaminants do not make their way into the sensitive components of the machinery. This guide delves into the intricate details of why choosing the ideal air filter is paramount and how it enhances operational effectiveness, tailored for field professionals seeking reliability and performance.

From years of experience in the field, it’s clear that regular inspection and maintenance of air filters are critical. Experts advocate checking filters every 250 hours of operation. This routine check helps in identifying clogging early on, ensuring the rig is operating under optimal conditions. Moreover, maintaining an inventory of replacement filters can prevent unexpected downtimes. Many experienced rig operators recommend having at least two spare filters per rig at all times, enabling swift replacement when needed without halting the operation. Authoritative Recommendations Industry leaders strongly suggest sourcing air filters from reputable manufacturers known for consistency and quality. For instance, brands with international certifications or those offering guarantees on performance can provide added peace of mind. Trusted brands also frequently offer advanced technologies like nanofiber layers which enhance filtration efficiency without sacrificing airflow. Building Trust Avoiding Common Pitfalls Trustworthiness is built by avoiding common pitfalls such as choosing low-cost, generic filters that have not been tested in real-world conditions. Such filters often lack the necessary reliability, compromising the rig's engines. Additionally, neglecting regular replacement intervals can lead to engine wear and tear, reducing the operational lifespan of the rig. Conclusion The choice of a drilling rig air filter significantly influences the rig's overall performance, longevity, and efficiency. By focusing on the right type, efficiency, and commitment to regular maintenance, professionals in the field can ensure their equipment runs smoothly under the most demanding conditions. By prioritizing quality and trusting established manufacturers, one effectively shields the rig's engines from the detrimental impacts of dirt and debris, safeguarding against productivity losses and unexpected expenses, and securing a reliable, efficient operation.

From years of experience in the field, it’s clear that regular inspection and maintenance of air filters are critical. Experts advocate checking filters every 250 hours of operation. This routine check helps in identifying clogging early on, ensuring the rig is operating under optimal conditions. Moreover, maintaining an inventory of replacement filters can prevent unexpected downtimes. Many experienced rig operators recommend having at least two spare filters per rig at all times, enabling swift replacement when needed without halting the operation. Authoritative Recommendations Industry leaders strongly suggest sourcing air filters from reputable manufacturers known for consistency and quality. For instance, brands with international certifications or those offering guarantees on performance can provide added peace of mind. Trusted brands also frequently offer advanced technologies like nanofiber layers which enhance filtration efficiency without sacrificing airflow. Building Trust Avoiding Common Pitfalls Trustworthiness is built by avoiding common pitfalls such as choosing low-cost, generic filters that have not been tested in real-world conditions. Such filters often lack the necessary reliability, compromising the rig's engines. Additionally, neglecting regular replacement intervals can lead to engine wear and tear, reducing the operational lifespan of the rig. Conclusion The choice of a drilling rig air filter significantly influences the rig's overall performance, longevity, and efficiency. By focusing on the right type, efficiency, and commitment to regular maintenance, professionals in the field can ensure their equipment runs smoothly under the most demanding conditions. By prioritizing quality and trusting established manufacturers, one effectively shields the rig's engines from the detrimental impacts of dirt and debris, safeguarding against productivity losses and unexpected expenses, and securing a reliable, efficient operation.

Next:

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: