ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 16, 2025 08:49 Back to list

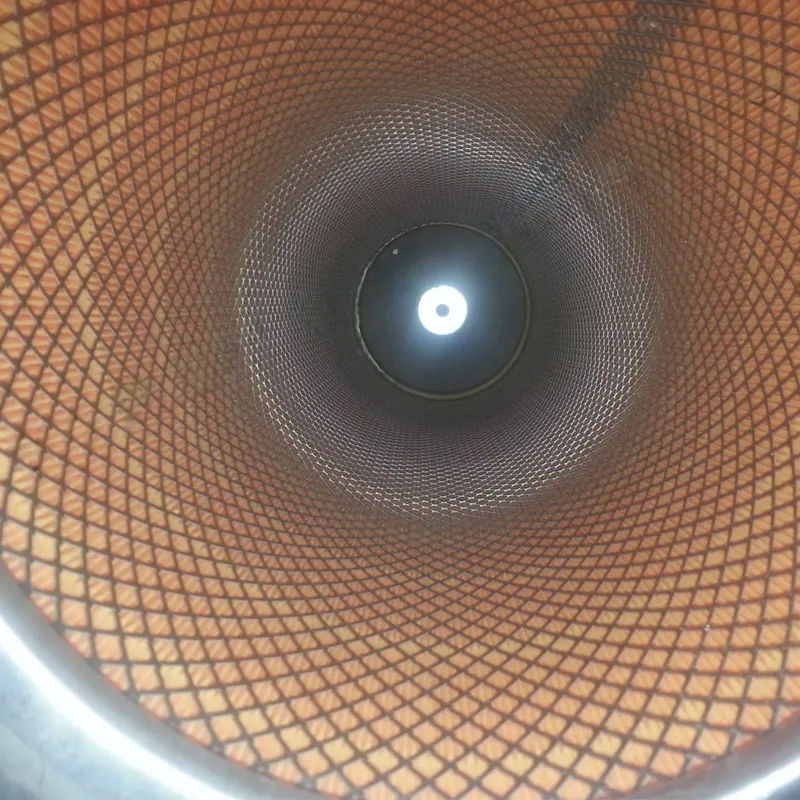

construction machines air filter

Every construction site thrives on efficiency, safety, and the performance of its machines. At the heart of many of these machines lies an often overlooked, yet critical component the air filter. A high-quality air filter is essential for maintaining the optimal performance of construction equipment, providing numerous benefits that extend to efficiency, longevity, and safety.

Expertise in selecting the right air filter is invaluable. With advancements in filter technology, options abound, each tailored to different specifications and environmental conditions. Understanding the needs of specific machines and the challenges posed by particular construction sites enables one to choose the most suitable air filter. It's not merely about picking a filter that fits; it’s about selecting one that enhances performance and aligns with operational goals. When it comes to trustworthiness and authority, opting for air filters from reputable manufacturers is imperative. Renowned brands invest heavily in research and development, ensuring their products not only meet but exceed industry standards. They provide reliable performance backed by warranty and support, offering peace of mind to owners and operators of construction machines. It's essential for construction companies to work closely with suppliers who can offer guidance based on real-world experience and technical know-how. A partnership with experts who understand both the technical and operational aspects of construction machinery can be invaluable. Such collaborations ensure that the air filters used are not just functional, but optimized for the specific demands of the project at hand. In conclusion, selecting the right air filter for construction machinery is both an art and a science, requiring attention to detail, expertise, and a commitment to quality. With the proper air filters in place, construction machines can operate at peak efficiency, safeguard their engines, and contribute to a safer work environment, ultimately leading to cost savings and project success. Making informed choices in this critical area reflects a commitment to excellence and an understanding of the nuances in maintaining construction equipment.

Expertise in selecting the right air filter is invaluable. With advancements in filter technology, options abound, each tailored to different specifications and environmental conditions. Understanding the needs of specific machines and the challenges posed by particular construction sites enables one to choose the most suitable air filter. It's not merely about picking a filter that fits; it’s about selecting one that enhances performance and aligns with operational goals. When it comes to trustworthiness and authority, opting for air filters from reputable manufacturers is imperative. Renowned brands invest heavily in research and development, ensuring their products not only meet but exceed industry standards. They provide reliable performance backed by warranty and support, offering peace of mind to owners and operators of construction machines. It's essential for construction companies to work closely with suppliers who can offer guidance based on real-world experience and technical know-how. A partnership with experts who understand both the technical and operational aspects of construction machinery can be invaluable. Such collaborations ensure that the air filters used are not just functional, but optimized for the specific demands of the project at hand. In conclusion, selecting the right air filter for construction machinery is both an art and a science, requiring attention to detail, expertise, and a commitment to quality. With the proper air filters in place, construction machines can operate at peak efficiency, safeguard their engines, and contribute to a safer work environment, ultimately leading to cost savings and project success. Making informed choices in this critical area reflects a commitment to excellence and an understanding of the nuances in maintaining construction equipment.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: