ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 02, 2025 02:31 Back to list

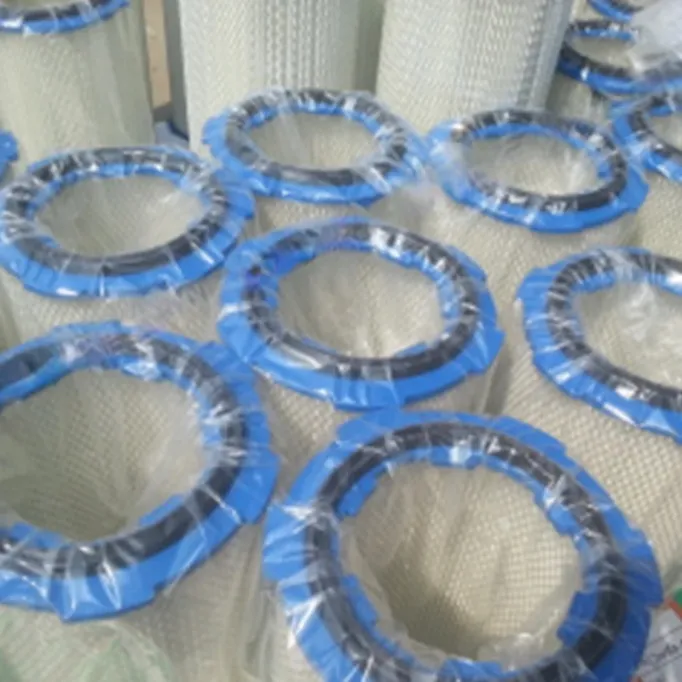

dust collector filter cartridge manufacturers

Cartridge filters for dust collectors have revolutionized industrial cleaning processes with their efficiency and reliability. Designed specifically to tackle varied dust and particulate matter, these filters have become a staple in industries such as manufacturing, woodworking, and pharmaceuticals. Harnessing the advantages of cutting-edge filtration technology, these cartridge filters are not only efficient in capturing dust but also prolong the life of machinery and enhance overall environmental quality.

Authoritative research has consistently highlighted the environmental benefits of cartridge filters. These filters are adept at capturing a higher percentage of airborne particles and contaminants compared to some conventional alternatives. This efficiency is crucial for maintaining compliance with stringent air quality regulations set by environmental agencies. Moreover, by minimizing dust and particulate release into the atmosphere, these filters contribute significantly to reducing the ecological footprint of industrial facilities. Trustworthiness in the context of cartridge filters is demonstrated through third-party certifications and adherence to international standards. Many reputable manufacturers test their filters according to standards such as ASHRAE and ISO to validate performance claims. This commitment to transparency and quality assurance ensures end-users that the products they are investing in meet rigorous performance benchmarks. Furthermore, regular maintenance guided by manufacturer recommendations ensures that the filters function optimally throughout their lifecycle, reinforcing their reliability and effectiveness. While the initial investment in cartridge filters may be slightly higher than other filtration options, the long-term savings in maintenance, energy, and compliance significantly outweigh the initial costs. An increasing number of facilities, especially those with high volumes of production, are switching to these systems for their unparalleled utility and performance stability. In summary, cartridge filters for dust collectors stand as a testament to modern engineering feats in the field of industrial filtration. Their adaptive design, sustained durability, and compliance with environmental standards make them an essential component for any facility focused on optimizing productivity and air quality. With ongoing advancements in filtration media and design, these filters promise to remain at the forefront of dust collection technology well into the future.

Authoritative research has consistently highlighted the environmental benefits of cartridge filters. These filters are adept at capturing a higher percentage of airborne particles and contaminants compared to some conventional alternatives. This efficiency is crucial for maintaining compliance with stringent air quality regulations set by environmental agencies. Moreover, by minimizing dust and particulate release into the atmosphere, these filters contribute significantly to reducing the ecological footprint of industrial facilities. Trustworthiness in the context of cartridge filters is demonstrated through third-party certifications and adherence to international standards. Many reputable manufacturers test their filters according to standards such as ASHRAE and ISO to validate performance claims. This commitment to transparency and quality assurance ensures end-users that the products they are investing in meet rigorous performance benchmarks. Furthermore, regular maintenance guided by manufacturer recommendations ensures that the filters function optimally throughout their lifecycle, reinforcing their reliability and effectiveness. While the initial investment in cartridge filters may be slightly higher than other filtration options, the long-term savings in maintenance, energy, and compliance significantly outweigh the initial costs. An increasing number of facilities, especially those with high volumes of production, are switching to these systems for their unparalleled utility and performance stability. In summary, cartridge filters for dust collectors stand as a testament to modern engineering feats in the field of industrial filtration. Their adaptive design, sustained durability, and compliance with environmental standards make them an essential component for any facility focused on optimizing productivity and air quality. With ongoing advancements in filtration media and design, these filters promise to remain at the forefront of dust collection technology well into the future.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: