ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 20, 2025 11:32 Back to list

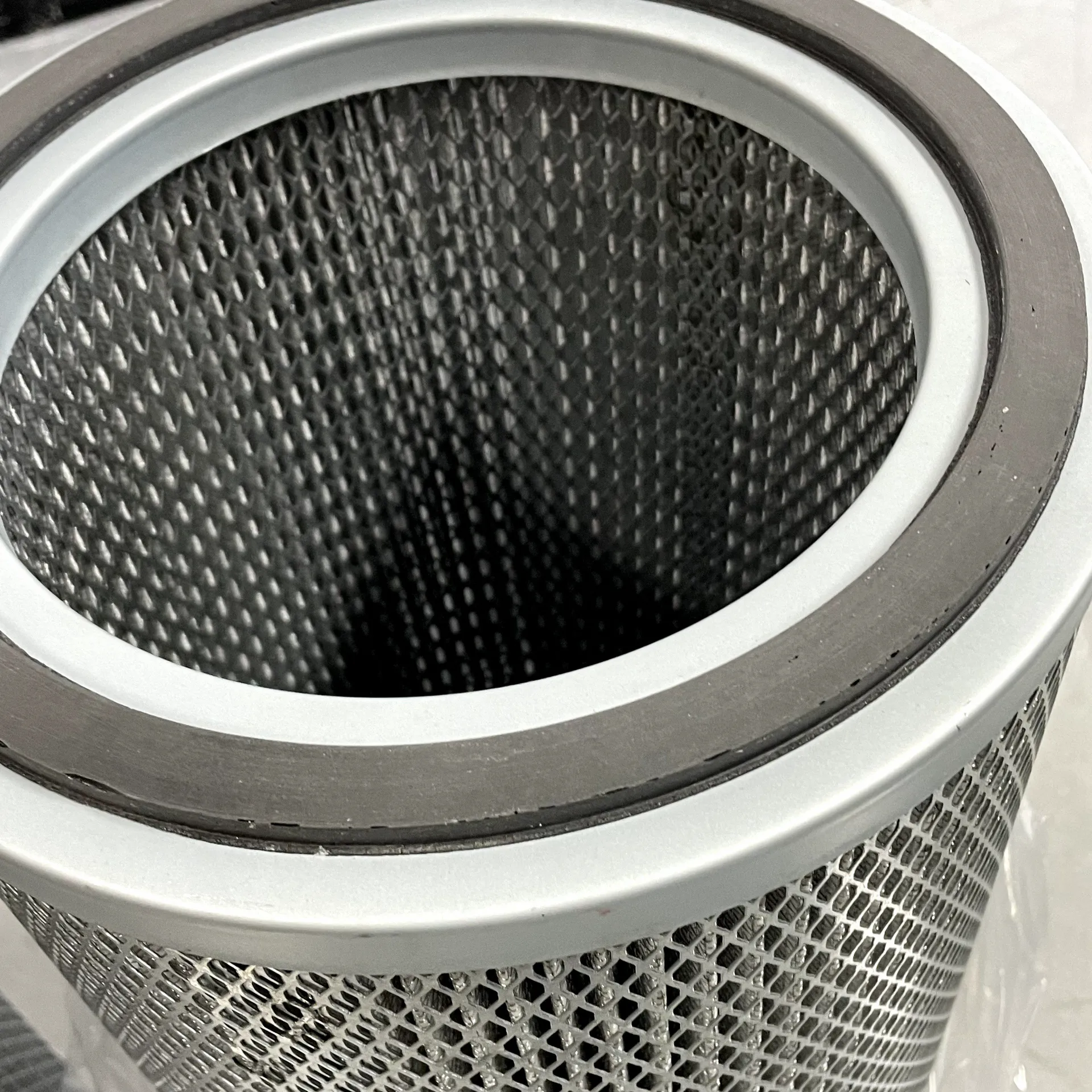

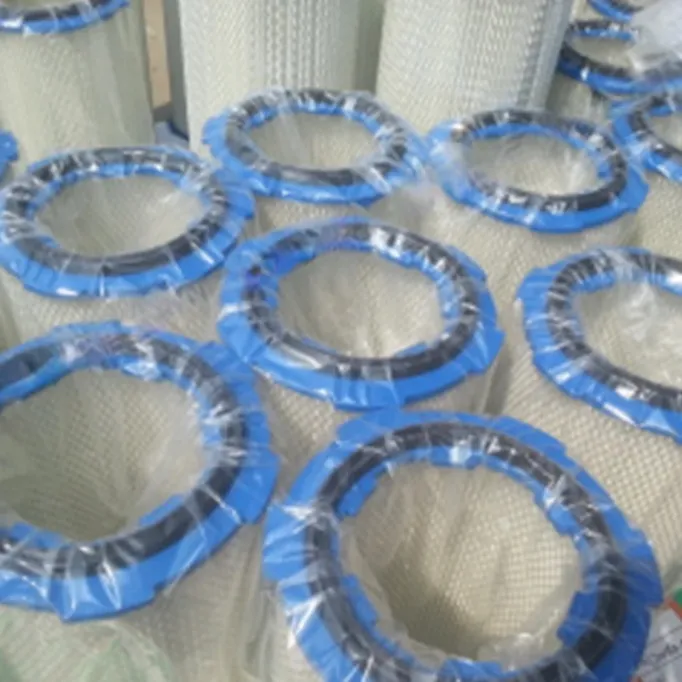

Easy Install Cylinder Shape activated carbon air filter cartridge

Maximizing Efficiency with Cartridge Dust Collector Filters

Expertise in handling these filters reveals their ability to outperform traditional bag filters by reducing operational costs. Cartridge filters require less frequent replacements due to their durability and ability to capture finer particles. They significantly improve air-to-cloth ratios, which is a measure of the airflow across the filter media relative to its surface area. This leads to increased efficiency, as the filters can handle larger volumes of air with less pressure drop. Authoritative sources in industrial filtration emphasize the importance of regular maintenance and cleaning. Pulse jet cleaning systems often accompany cartridge filters, where short blasts of compressed air reduce dust build-up, prolonging the filter life. This method ensures that operational efficiency is not compromised over time. Furthermore, experts advocate for regular inspections and interval-based replacements to prevent system downtimes and maintain compliance with occupational health standards. Trustworthiness in implementing cartridge dust collector filters is evidenced by their widespread adoption across industries. Testimonials from manufacturing and processing plants highlight reduced energy costs and improved worker health and safety as primary benefits. For businesses seeking reliable and efficient dust control solutions, cartridge filters prove their mettle by meeting rigorous environmental and safety regulations. In summary, cartridge dust collector filters are indispensable in achieving a balance between efficiency and safety in industrial environments. An informed selection process supported by expert advice ensures that these filters deliver optimal performance. Their ability to significantly enhance air quality while minimizing operational expenses aligns perfectly with contemporary business goals of sustainability and worker safety. Embracing these advanced filters translates into tangible benefits, underscoring their role as a cornerstone in effective dust management strategies.

Expertise in handling these filters reveals their ability to outperform traditional bag filters by reducing operational costs. Cartridge filters require less frequent replacements due to their durability and ability to capture finer particles. They significantly improve air-to-cloth ratios, which is a measure of the airflow across the filter media relative to its surface area. This leads to increased efficiency, as the filters can handle larger volumes of air with less pressure drop. Authoritative sources in industrial filtration emphasize the importance of regular maintenance and cleaning. Pulse jet cleaning systems often accompany cartridge filters, where short blasts of compressed air reduce dust build-up, prolonging the filter life. This method ensures that operational efficiency is not compromised over time. Furthermore, experts advocate for regular inspections and interval-based replacements to prevent system downtimes and maintain compliance with occupational health standards. Trustworthiness in implementing cartridge dust collector filters is evidenced by their widespread adoption across industries. Testimonials from manufacturing and processing plants highlight reduced energy costs and improved worker health and safety as primary benefits. For businesses seeking reliable and efficient dust control solutions, cartridge filters prove their mettle by meeting rigorous environmental and safety regulations. In summary, cartridge dust collector filters are indispensable in achieving a balance between efficiency and safety in industrial environments. An informed selection process supported by expert advice ensures that these filters deliver optimal performance. Their ability to significantly enhance air quality while minimizing operational expenses aligns perfectly with contemporary business goals of sustainability and worker safety. Embracing these advanced filters translates into tangible benefits, underscoring their role as a cornerstone in effective dust management strategies.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: