ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 02, 2025 05:19 Back to list

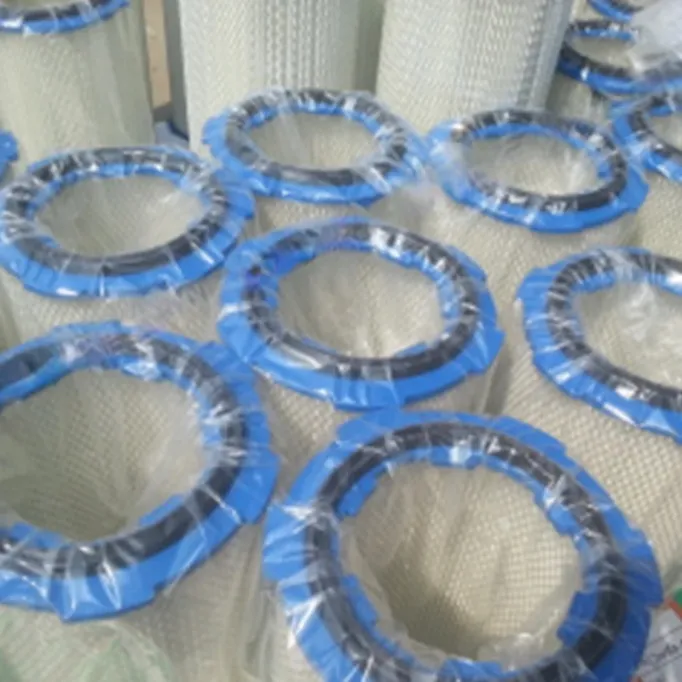

Air Filter High Performance Dust air compressor filter cartridge

Cartridge air filters are essential components in various machines and appliances, playing a critical role in ensuring optimal performance and longevity. These filters are pivotal in industries such as automotive, manufacturing, and home air purification systems. This article will delve into the multifaceted world of cartridge air filters, highlighting their importance and offering insights drawn from extensive experience in their application and maintenance.

The authority of cartridge air filter manufacturers comes from their rigorous testing and compliance with international standards such as ISO 5011. This ensures their products can handle specific demands of various applications, from heavy-duty trucking to delicate laboratory settings. Companies like Donaldson and K&N invest heavily in research and development, using state-of-the-art technology to produce filters that not only meet but exceed industry standards. Their commitment to innovation and quality is reflected in the trust consumers place in their products. Trustworthiness is further amplified through certifications and endorsements from vehicle manufacturers and industry associations. When selecting a cartridge air filter, it's prudent to consider products that are OEM (Original Equipment Manufacturer) certified, ensuring compatibility and reliability. Additionally, reviews and user testimonials provide valuable insights into the performance and longevity of specific filter brands and models. To optimize the selection of a cartridge air filter, professionals suggest considering factors such as the operating environment, the type of machinery, and specific performance requirements. For instance, high-performance vehicles might benefit from filters designed to maximize airflow, while heavy machinery in construction might require robust filters capable of withstanding heavy dust loads. In summary, the world of cartridge air filters is complex yet fascinating, bridging the gap between simple filtration and advanced technology designed to meet diverse industrial needs. Their role in protecting engines and machinery while optimizing performance underscores their importance in any maintenance regime. By leveraging experience, expertise, and a commitment to quality, users can ensure that their choice of filter not only meets their immediate needs but also contributes to long-term operational efficiency and cost-effectiveness.

The authority of cartridge air filter manufacturers comes from their rigorous testing and compliance with international standards such as ISO 5011. This ensures their products can handle specific demands of various applications, from heavy-duty trucking to delicate laboratory settings. Companies like Donaldson and K&N invest heavily in research and development, using state-of-the-art technology to produce filters that not only meet but exceed industry standards. Their commitment to innovation and quality is reflected in the trust consumers place in their products. Trustworthiness is further amplified through certifications and endorsements from vehicle manufacturers and industry associations. When selecting a cartridge air filter, it's prudent to consider products that are OEM (Original Equipment Manufacturer) certified, ensuring compatibility and reliability. Additionally, reviews and user testimonials provide valuable insights into the performance and longevity of specific filter brands and models. To optimize the selection of a cartridge air filter, professionals suggest considering factors such as the operating environment, the type of machinery, and specific performance requirements. For instance, high-performance vehicles might benefit from filters designed to maximize airflow, while heavy machinery in construction might require robust filters capable of withstanding heavy dust loads. In summary, the world of cartridge air filters is complex yet fascinating, bridging the gap between simple filtration and advanced technology designed to meet diverse industrial needs. Their role in protecting engines and machinery while optimizing performance underscores their importance in any maintenance regime. By leveraging experience, expertise, and a commitment to quality, users can ensure that their choice of filter not only meets their immediate needs but also contributes to long-term operational efficiency and cost-effectiveness.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: