ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

1 月 . 24, 2025 05:03 Back to list

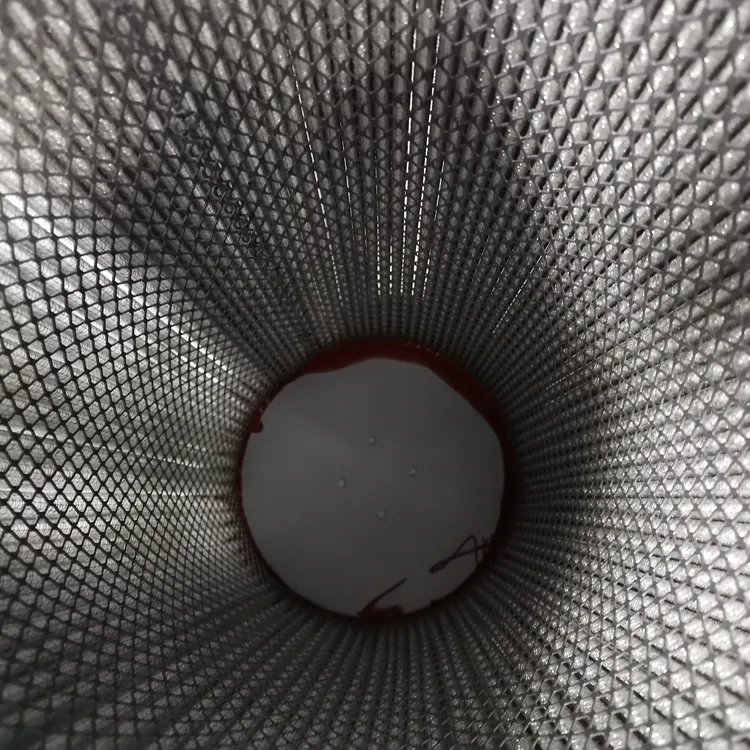

Air Filter High Performance Dust air compressor filter cartridge

Choosing the right cartridge air filter is essential for ensuring the longevity and efficiency of any machinery or engine it serves. With a myriad of options available, making an informed choice can significantly impact performance, fuel efficiency, and the lifespan of your equipment. Through expert insights and real-world experiences, this article aims to guide you through the nuances of selecting and maintaining a cartridge air filter, underscoring the importance of expertise and trustworthiness in your decision-making process.

For authoritative guidance, it is advisable to consult OEM (Original Equipment Manufacturer) recommendations, ensuring that the filter meets specific requirements set by the manufacturer. Installers and mechanics with years of experience in the industry advise adherence to these guidelines to avoid voiding warranties and to maximize engine performance. These insights emphasize the importance of expertise, as incorrect filter selection or poor installation can lead to increased maintenance costs and equipment downtime. Maintenance plays a pivotal role in ensuring the longevity and efficiency of cartridge air filters. Regular inspections are recommended to detect signs of wear or blockages early on. Experts advocate for timely replacements and using high-quality sealants during installation to prevent air leaks. Recently, technology has facilitated this process with sensors that alert users when a filter change is imminent, integrating seamlessly into maintenance schedules and thereby enhancing trust in the product's effectiveness. In conclusion, the choice and maintenance of a cartridge air filter should be guided by informed expert opinions, backed by user testimonials and adherence to authoritative guidelines. Investing in a high-quality filter not only protects and enhances your machinery's performance but also embodies a commitment to maintaining peak operational standards through trusted and expert-endorsed products.

For authoritative guidance, it is advisable to consult OEM (Original Equipment Manufacturer) recommendations, ensuring that the filter meets specific requirements set by the manufacturer. Installers and mechanics with years of experience in the industry advise adherence to these guidelines to avoid voiding warranties and to maximize engine performance. These insights emphasize the importance of expertise, as incorrect filter selection or poor installation can lead to increased maintenance costs and equipment downtime. Maintenance plays a pivotal role in ensuring the longevity and efficiency of cartridge air filters. Regular inspections are recommended to detect signs of wear or blockages early on. Experts advocate for timely replacements and using high-quality sealants during installation to prevent air leaks. Recently, technology has facilitated this process with sensors that alert users when a filter change is imminent, integrating seamlessly into maintenance schedules and thereby enhancing trust in the product's effectiveness. In conclusion, the choice and maintenance of a cartridge air filter should be guided by informed expert opinions, backed by user testimonials and adherence to authoritative guidelines. Investing in a high-quality filter not only protects and enhances your machinery's performance but also embodies a commitment to maintaining peak operational standards through trusted and expert-endorsed products.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: