ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

3 月 . 05, 2025 07:21 Back to list

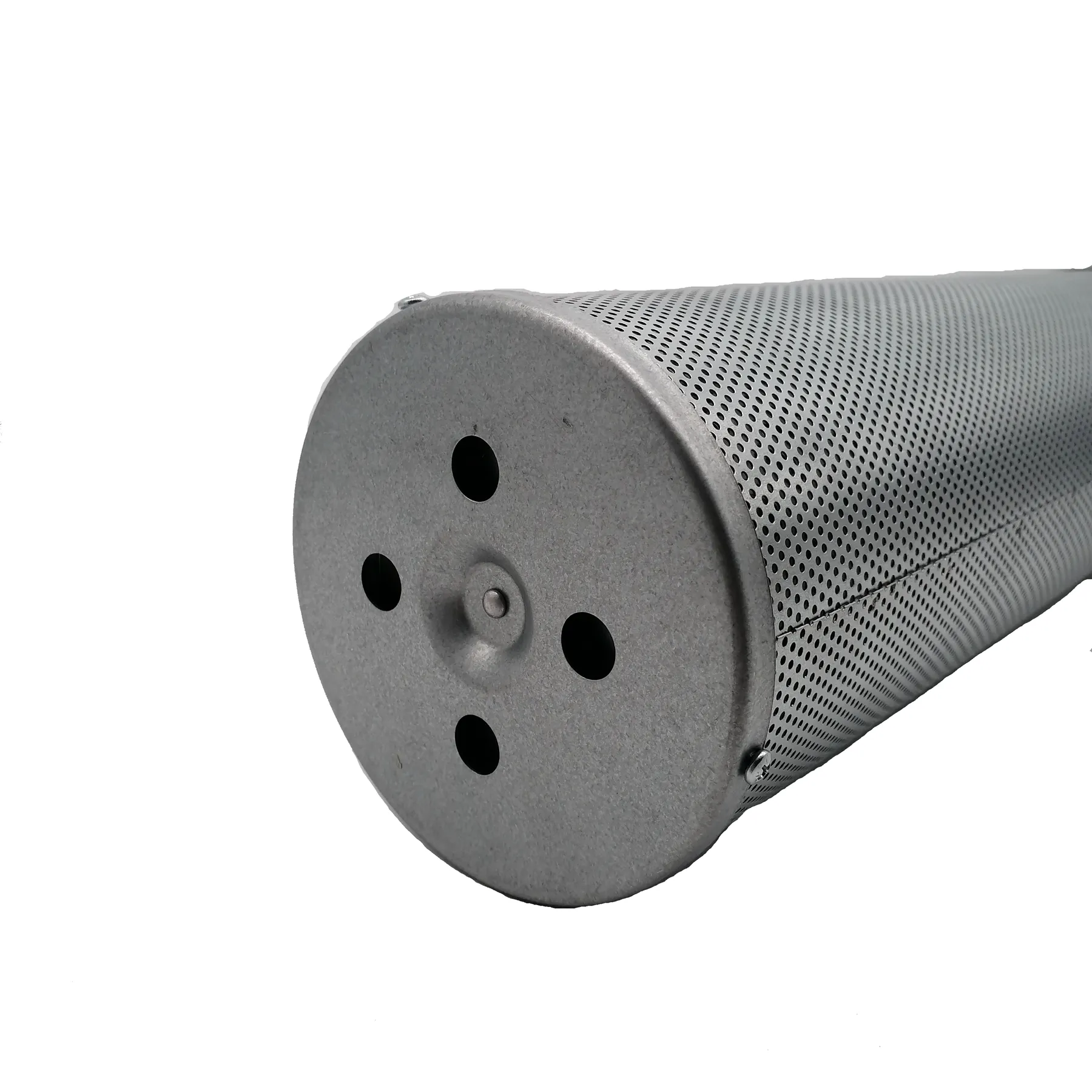

Air Filter High Performance Dust air compressor filter cartridge

The evolution of filtration technology has brought about innovative solutions designed to address specific industrial challenges. Among these advancements, the anti-static filter cartridge stands out as a specialized product that addresses both the need for efficient filtration and the risks associated with static discharge in various applications.

Real-world experience has proven the trustworthiness of anti-static filter cartridges across various applications. For instance, in the pharmaceutical industry, where airborne particulates and electrostatic charges could potentially lead to safety hazards or product contamination, these cartridges have become indispensable. Similarly, in the chemical manufacturing sector, the use of anti-static cartridges avoids the accumulation of potentially hazardous dust, thereby ensuring a safer working environment. Furthermore, the trustworthiness of these cartridges is often validated by compliance with international safety standards. Products are frequently subjected to rigorous testing and certification processes that affirm their capability to meet industry safety requirements. These certifications not only enhance customer confidence but also demonstrate a commitment to maintaining high standards of safety and efficiency. Choosing the right anti-static filter cartridge involves understanding specific operational needs and consulting with professionals who specialize in filtration technology. Expertise in this field ensures that the selected product meets the operational demands while adhering to safety protocols. Collaboration with reputable manufacturers and suppliers further guarantees that the product will perform as expected in demanding environments. In conclusion, the anti-static filter cartridge is a testament to how innovative solutions can elevate both safety and performance in industrial applications. As industries continue to evolve and face new challenges, the need for specialized products like these cartridges becomes even more critical. Investing in anti-static filter cartridges is not just a decision for improved filtration but a strategic move towards safeguarding operational integrity, reducing risks, and ensuring compliance with stringent industry standards.

Real-world experience has proven the trustworthiness of anti-static filter cartridges across various applications. For instance, in the pharmaceutical industry, where airborne particulates and electrostatic charges could potentially lead to safety hazards or product contamination, these cartridges have become indispensable. Similarly, in the chemical manufacturing sector, the use of anti-static cartridges avoids the accumulation of potentially hazardous dust, thereby ensuring a safer working environment. Furthermore, the trustworthiness of these cartridges is often validated by compliance with international safety standards. Products are frequently subjected to rigorous testing and certification processes that affirm their capability to meet industry safety requirements. These certifications not only enhance customer confidence but also demonstrate a commitment to maintaining high standards of safety and efficiency. Choosing the right anti-static filter cartridge involves understanding specific operational needs and consulting with professionals who specialize in filtration technology. Expertise in this field ensures that the selected product meets the operational demands while adhering to safety protocols. Collaboration with reputable manufacturers and suppliers further guarantees that the product will perform as expected in demanding environments. In conclusion, the anti-static filter cartridge is a testament to how innovative solutions can elevate both safety and performance in industrial applications. As industries continue to evolve and face new challenges, the need for specialized products like these cartridges becomes even more critical. Investing in anti-static filter cartridges is not just a decision for improved filtration but a strategic move towards safeguarding operational integrity, reducing risks, and ensuring compliance with stringent industry standards.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: