ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

1 月 . 19, 2025 01:17 Back to list

air to cloth ratio for cartridge filter

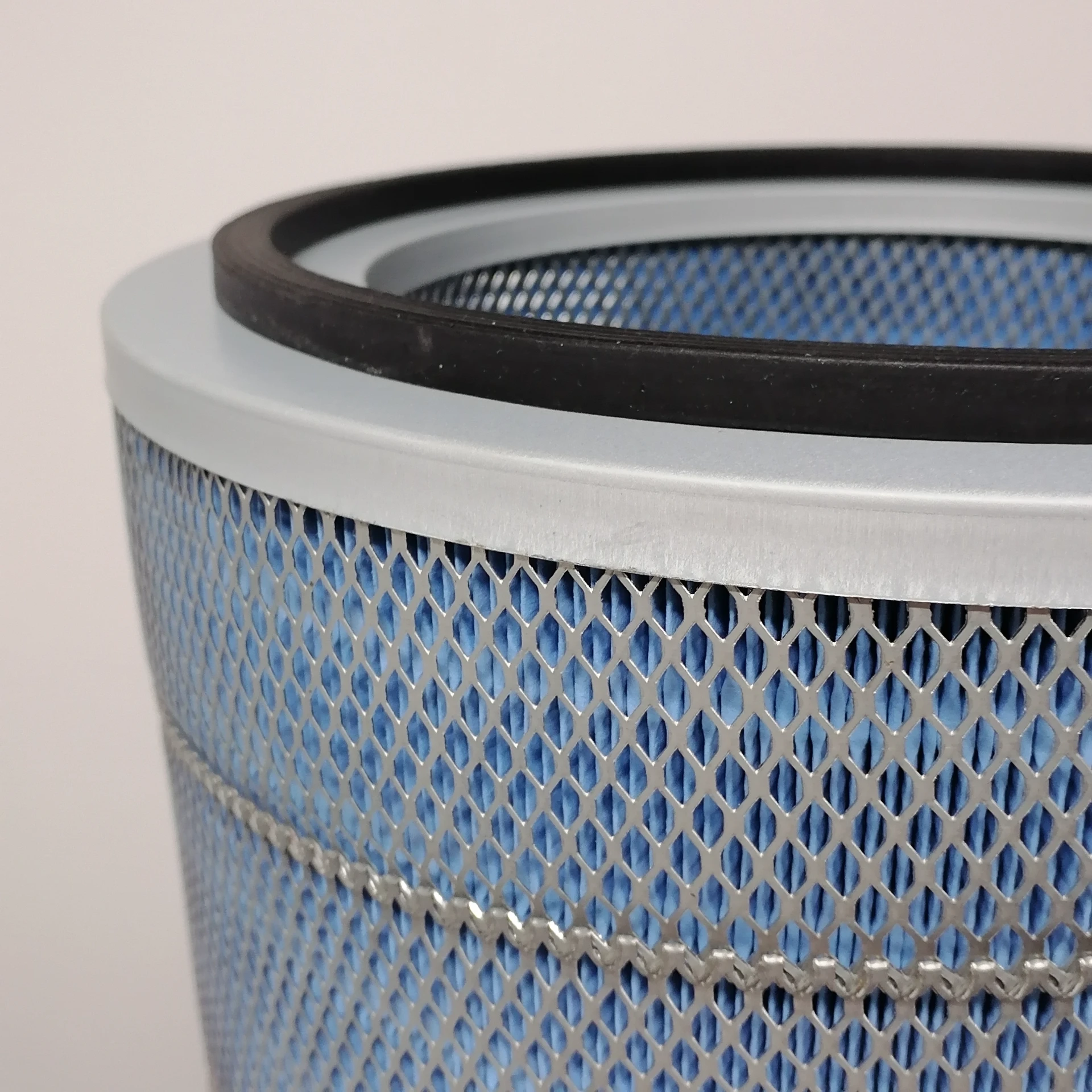

Air to cloth ratio is a pivotal parameter in the design and functioning of cartridge filters. These filters, integral to various industrial applications, rely on achieving an optimal balance between air flow and filtration efficiency. Understanding the dynamics of air to cloth ratio not only influences product performance but also extends the operational life of the filtration unit.

Authoritativeness is also established through standards and recommendations. Industry standards, such as those from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) or the Occupational Safety and Health Administration (OSHA), provide guidelines that help determine optimal air to cloth ratios for various applications. By adhering to these standards, businesses can ensure they meet regulatory requirements while optimizing efficiency. Moreover, leveraging advancements in filtration technology can also play a role. The advent of nanofiber filter media has allowed for higher air to cloth ratios without sacrificing efficiency, offering an innovative solution for industries dealing with sub-micron particulates. Thus, selecting the appropriate filter media based on the working environment and desired performance outcomes can significantly enhance filtration results. Trustworthiness in managing air to cloth ratios comes from consistency and monitoring. Implementing routine checks and employing data-driven approaches using sensors and digital tracking systems can alert operators to deviations in the ratio, allowing for timely interventions. A proactive measure such as predictive maintenance schedules ensures the filter systems operate within the predetermined air to cloth parameters, thereby maximizing both efficiency and filter life. Furthermore, training personnel in understanding and managing air to cloth ratios elevates the operational efficacy of cartridge filters. Employees knowledgeable in the nuances of air flow dynamics and filtration principles are better equipped to identify potential issues, make recommendations, and implement solutions effectively. In summary, the air to cloth ratio is a cornerstone concept in the realm of cartridge filters, mandating a blend of insightful planning and continuous management. Precision in calibrating this ratio aligns product performance with industry benchmarks, fostering a robust filtration system that upholds both safety and productivity. The journey to mastering air to cloth ratio begins with education, adherence to standards, intelligent use of technology, and a commitment to regular monitoring and maintenance. As industries evolve, staying abreast of technological innovations and regulatory changes will further fortify filtration efficacy, cementing a legacy of excellence and reliability in air quality management across sectors.

Authoritativeness is also established through standards and recommendations. Industry standards, such as those from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) or the Occupational Safety and Health Administration (OSHA), provide guidelines that help determine optimal air to cloth ratios for various applications. By adhering to these standards, businesses can ensure they meet regulatory requirements while optimizing efficiency. Moreover, leveraging advancements in filtration technology can also play a role. The advent of nanofiber filter media has allowed for higher air to cloth ratios without sacrificing efficiency, offering an innovative solution for industries dealing with sub-micron particulates. Thus, selecting the appropriate filter media based on the working environment and desired performance outcomes can significantly enhance filtration results. Trustworthiness in managing air to cloth ratios comes from consistency and monitoring. Implementing routine checks and employing data-driven approaches using sensors and digital tracking systems can alert operators to deviations in the ratio, allowing for timely interventions. A proactive measure such as predictive maintenance schedules ensures the filter systems operate within the predetermined air to cloth parameters, thereby maximizing both efficiency and filter life. Furthermore, training personnel in understanding and managing air to cloth ratios elevates the operational efficacy of cartridge filters. Employees knowledgeable in the nuances of air flow dynamics and filtration principles are better equipped to identify potential issues, make recommendations, and implement solutions effectively. In summary, the air to cloth ratio is a cornerstone concept in the realm of cartridge filters, mandating a blend of insightful planning and continuous management. Precision in calibrating this ratio aligns product performance with industry benchmarks, fostering a robust filtration system that upholds both safety and productivity. The journey to mastering air to cloth ratio begins with education, adherence to standards, intelligent use of technology, and a commitment to regular monitoring and maintenance. As industries evolve, staying abreast of technological innovations and regulatory changes will further fortify filtration efficacy, cementing a legacy of excellence and reliability in air quality management across sectors.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: