ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

1 月 . 19, 2025 04:02 Back to list

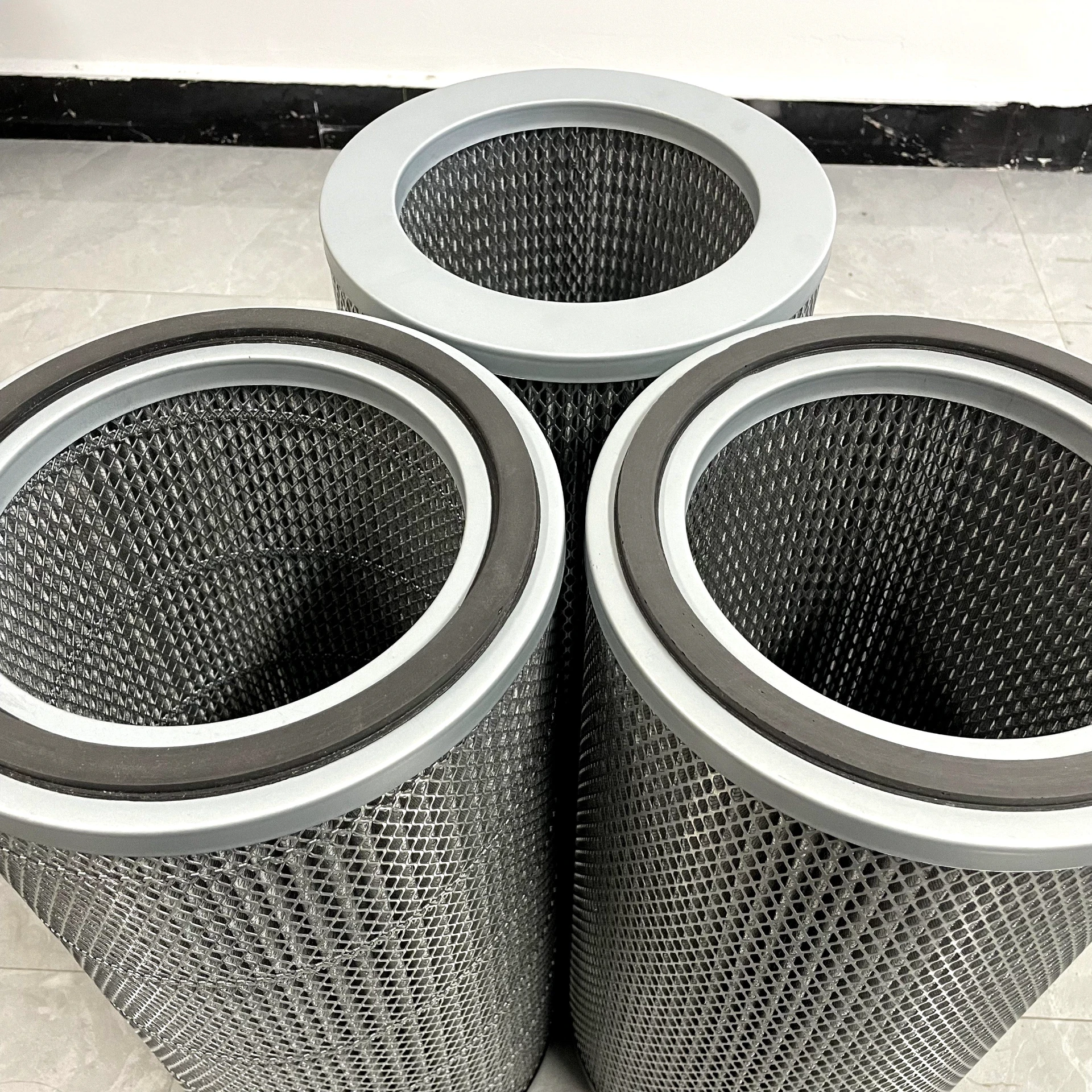

Low cost durable air filter for gas turbine

Gas turbines play a crucial role in the energy sector, providing power to a range of industries due to their efficiency and capacity to produce large amounts of energy. One critical component that significantly impacts the performance and longevity of a gas turbine is the air filter. Choosing the right air filter not only ensures optimal performance but also extends the lifespan of the turbine, ultimately saving time and resources. Here's a comprehensive look into the importance of air filters for gas turbines and guidance on selecting the right one.

Advanced air filter technology, such as HEPA or ULPA filters, is designed for high-efficiency particle arresting, helping turbines to perform in optimal condition even in the most challenging environments. These filters are often constructed using advanced synthetic materials with electrostatic properties that enhance particle capture without significantly impeding air flow. Moreover, regular maintenance and monitoring of air filters are essential to ensure they function effectively over time. Clogged or saturated filters not only compromise airflow, thus reducing turbine efficiency, but can also lead to overheating and increased fuel consumption. This is why employing a proactive maintenance schedule that includes regular inspection and replacement of filters is crucial. To assert expertise and ensure trustworthiness, manufacturers and suppliers of air filters often provide detailed product specifications, including pressure drop data, filtration efficiency, and expected operational life under specific conditions. Engaging with suppliers that offer not only high-quality products but also robust technical support and consultancy can ensure that the most suitable solutions are deployed for any given application. In summary, air filters are a pivotal component in maintaining the efficiency and reliability of gas turbines. By understanding and prioritizing factors such as filtration efficiency, environmental conditions, and proactive maintenance, industry professionals can make informed decisions that optimize performance while safeguarding their investment. Whether operating in adverse environmental conditions or facing unique industrial challenges, selecting the right air filter can lead to substantial long-term benefits in turbine operation.

Advanced air filter technology, such as HEPA or ULPA filters, is designed for high-efficiency particle arresting, helping turbines to perform in optimal condition even in the most challenging environments. These filters are often constructed using advanced synthetic materials with electrostatic properties that enhance particle capture without significantly impeding air flow. Moreover, regular maintenance and monitoring of air filters are essential to ensure they function effectively over time. Clogged or saturated filters not only compromise airflow, thus reducing turbine efficiency, but can also lead to overheating and increased fuel consumption. This is why employing a proactive maintenance schedule that includes regular inspection and replacement of filters is crucial. To assert expertise and ensure trustworthiness, manufacturers and suppliers of air filters often provide detailed product specifications, including pressure drop data, filtration efficiency, and expected operational life under specific conditions. Engaging with suppliers that offer not only high-quality products but also robust technical support and consultancy can ensure that the most suitable solutions are deployed for any given application. In summary, air filters are a pivotal component in maintaining the efficiency and reliability of gas turbines. By understanding and prioritizing factors such as filtration efficiency, environmental conditions, and proactive maintenance, industry professionals can make informed decisions that optimize performance while safeguarding their investment. Whether operating in adverse environmental conditions or facing unique industrial challenges, selecting the right air filter can lead to substantial long-term benefits in turbine operation.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: