Tel:

+8618931101301

Tel:

+8618931101301

12 月 . 03, 2024 18:33 Back to list

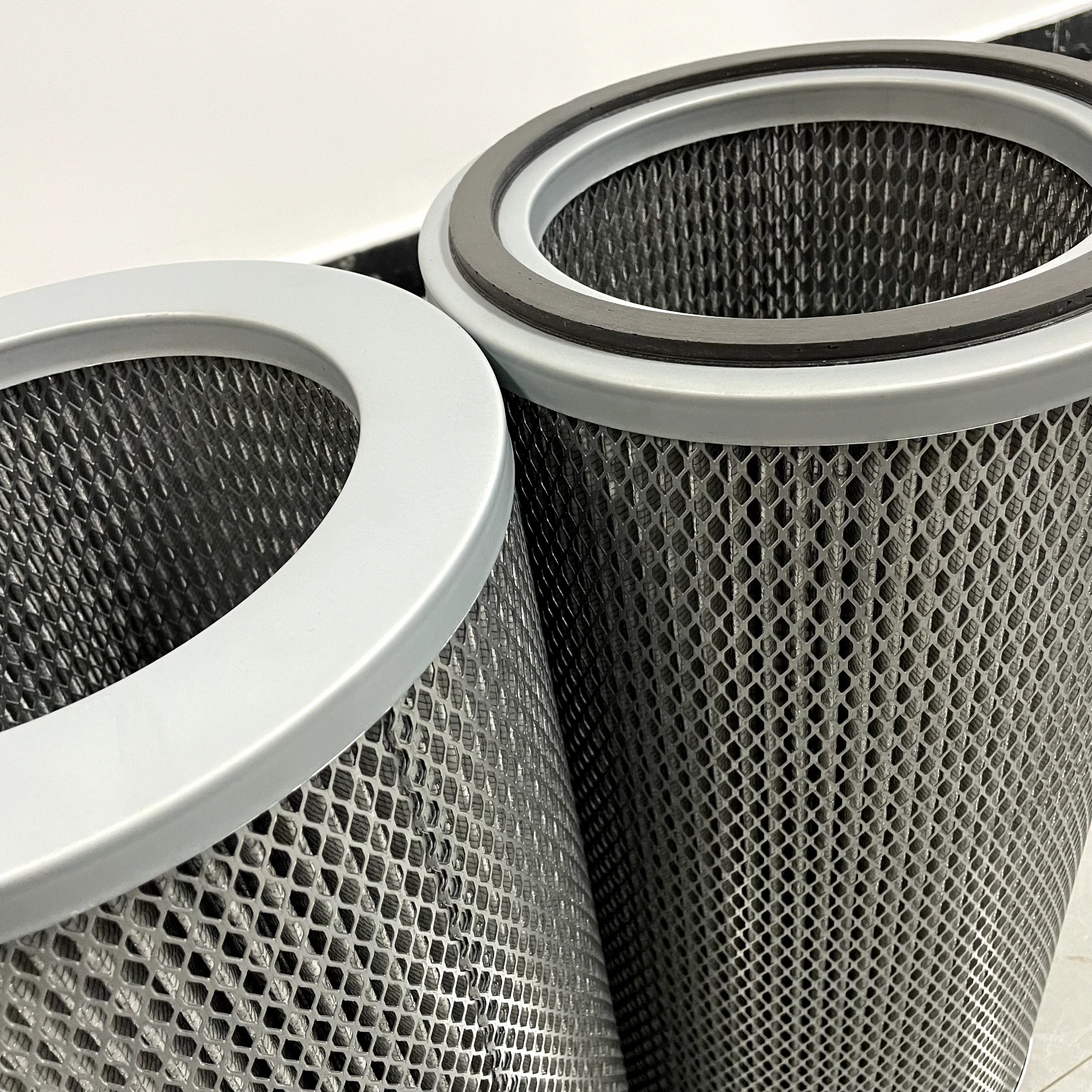

air filter for excavator

The Importance of Air Filters for Excavators

Excavators are essential machinery in construction, mining, and various other industrial applications. They are designed to perform heavy lifting, digging, and earth-moving tasks with efficiency and precision. However, like all heavy machinery, excavators require regular maintenance to ensure optimal performance and longevity. One critical component that often gets overlooked is the air filter. In this article, we will explore the vital role of air filters in excavators, their impact on performance, and the importance of regular maintenance and replacement.

Understanding Air Filters

Air filters are designed to trap dust, dirt, and other contaminants before they can enter the engine's air intake system. An excavator's engine requires a clean supply of air for efficient combustion, which is why the integrity of the air filter is crucial. If the air filter becomes clogged, it can lead to a myriad of performance issues, including reduced engine power, increased fuel consumption, and even potential engine damage over time.

The Role of Air Filters in Performance

1. Engine Efficiency The engine in an excavator relies on a precise air-fuel mixture to operate effectively. A clean air filter allows the engine to draw in the right amount of air, promoting efficient combustion. If the air filter is compromised, the engine may not receive enough air, causing it to run rich, which negatively impacts performance and efficiency.

2. Fuel Economy A clogged air filter can significantly affect fuel economy. When an engine struggles to receive adequate air, it compensates by burning more fuel. This increase in consumption not only raises operational costs but can also have environmental implications.

3. Engine Longevity Over time, dirt and debris that bypass a dirty air filter can cause wear and tear on engine components. Particles can scratch cylinder walls or clog fuel injectors, leading to costly repairs and downtime. Regularly replacing the air filter can help extend the lifespan of the engine and prevent premature failure.

4. Reduced Emissions An efficient air filter contributes to the overall performance of an excavator, leading to better combustion and reduced emissions. This is particularly important in today’s regulatory environment, where heavy machinery must comply with stringent emissions standards.

air filter for excavator

Signs of a Worn or Clogged Air Filter

Regular monitoring of the air filter can help operators identify when it’s time for a replacement. Common signs of a clogged air filter include

- Decreased Engine Performance If the excavator struggles to maintain power, especially during heavy lifting tasks, the air filter may be the culprit. - Increased Fuel Consumption A noticeable uptick in fuel use without changes in workload can indicate an issue with the air intake system. - Check Engine Light Modern excavators equipped with advanced diagnostic systems may alert operators to air filter problems via warning lights. - Visible Dirt and Damage A visual inspection can often reveal dirt buildup or physical damage to the filter, indicating it’s time for a replacement.

Maintenance and Replacement

To maintain optimal performance, excavator operators should establish a regular maintenance schedule that includes inspecting and replacing the air filter as needed. The frequency of replacement can vary depending on the operating environment—dusty job sites may necessitate more frequent changes than cleaner conditions.

Proper cleaning and installation techniques should also be observed. Using OEM (original equipment manufacturer) air filters is recommended, as these products are designed specifically for the excavator model, ensuring the best fit and function.

Conclusion

In summary, air filters play a crucial role in the overall performance and efficiency of excavators. They contribute to engine efficiency, fuel economy, longevity, and compliance with emissions standards. Regular maintenance and timely replacement of the air filter can prevent performance issues and extend the life of the machine. By investing in proper care for this essential component, operators can ensure their excavators remain in optimal condition, avoiding costly repairs and maximizing productivity on the job site.

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Email:

Email: