ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 13, 2025 16:48 Back to list

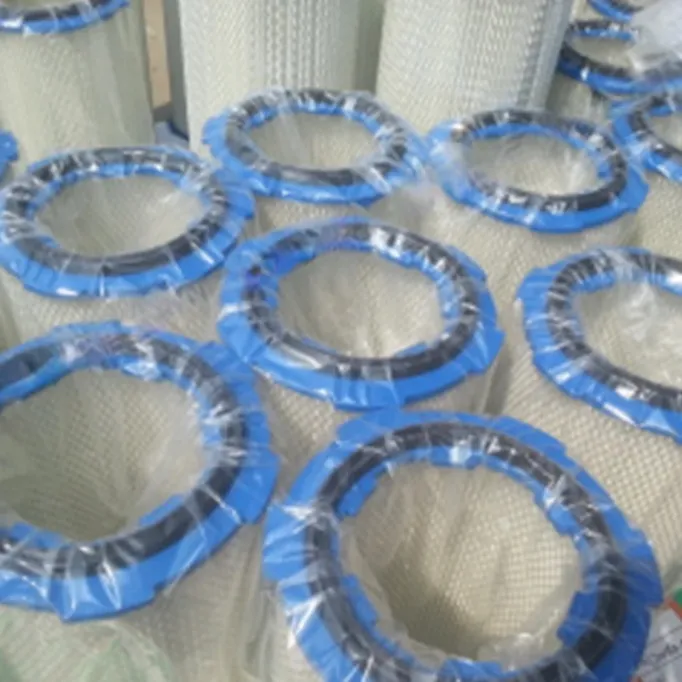

Air Filter High Performance Dust air compressor filter cartridge

Air compressors are essential tools across various industries, providing a steady stream of compressed air for applications ranging from powering pneumatic tools to inflating tires. Central to their efficient operation is the air compressor filter cartridge, a component often overlooked yet crucial for maintaining performance and longevity. With years of industry experience, I underscore the significance of choosing the right filter cartridge, examining its impact, qualities, and maintenance.

Furthermore, maintaining the filter cartridge enhances its functionality and extends the life of the air compressor. Regular inspections and timely replacements are crucial. Experts recommend checking the filter’s condition frequently and replacing it in accordance with the manufacturer’s advised intervals, or earlier if signs of clogging or damage are evident. A neglected filter can lead to restricted airflow, increased energy consumption, and subsequent system inefficiencies. To gain practical insights, let us explore a case study highlighting significant improvements in a manufacturing plant’s air compressor operation post-filter upgrade. After experiencing frequent machinery downtimes due to air contamination, the plant opted for premium coalescing and particulate filters tailored to their specific operational needs. The result was a remarkable decrease in machine malfunctions and maintenance costs, underscoring the profound effect a suitable air compressor filter cartridge can have on a business’s bottom line. Ultimately, the air compressor filter cartridge is not a mere accessory but a critical component influencing the efficiency, quality, and lifespan of the entire air compression system. By leveraging personal experience, industry expertise, and authoritative guidelines, users can make informed decisions that safeguard their investments and enhance productive outcomes. Conclusively, a meticulous approach towards selecting and maintaining an air compressor filter cartridge transforms it into a linchpin of operational efficiency. Emphasizing expert recommendations and proactive maintenance not only proves economically beneficial but also fortifies the trust and dependability expected from your air compressor system.

Furthermore, maintaining the filter cartridge enhances its functionality and extends the life of the air compressor. Regular inspections and timely replacements are crucial. Experts recommend checking the filter’s condition frequently and replacing it in accordance with the manufacturer’s advised intervals, or earlier if signs of clogging or damage are evident. A neglected filter can lead to restricted airflow, increased energy consumption, and subsequent system inefficiencies. To gain practical insights, let us explore a case study highlighting significant improvements in a manufacturing plant’s air compressor operation post-filter upgrade. After experiencing frequent machinery downtimes due to air contamination, the plant opted for premium coalescing and particulate filters tailored to their specific operational needs. The result was a remarkable decrease in machine malfunctions and maintenance costs, underscoring the profound effect a suitable air compressor filter cartridge can have on a business’s bottom line. Ultimately, the air compressor filter cartridge is not a mere accessory but a critical component influencing the efficiency, quality, and lifespan of the entire air compression system. By leveraging personal experience, industry expertise, and authoritative guidelines, users can make informed decisions that safeguard their investments and enhance productive outcomes. Conclusively, a meticulous approach towards selecting and maintaining an air compressor filter cartridge transforms it into a linchpin of operational efficiency. Emphasizing expert recommendations and proactive maintenance not only proves economically beneficial but also fortifies the trust and dependability expected from your air compressor system.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: