ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8618931101301

Tel:

+8618931101301

2 月 . 10, 2025 19:50 Back to list

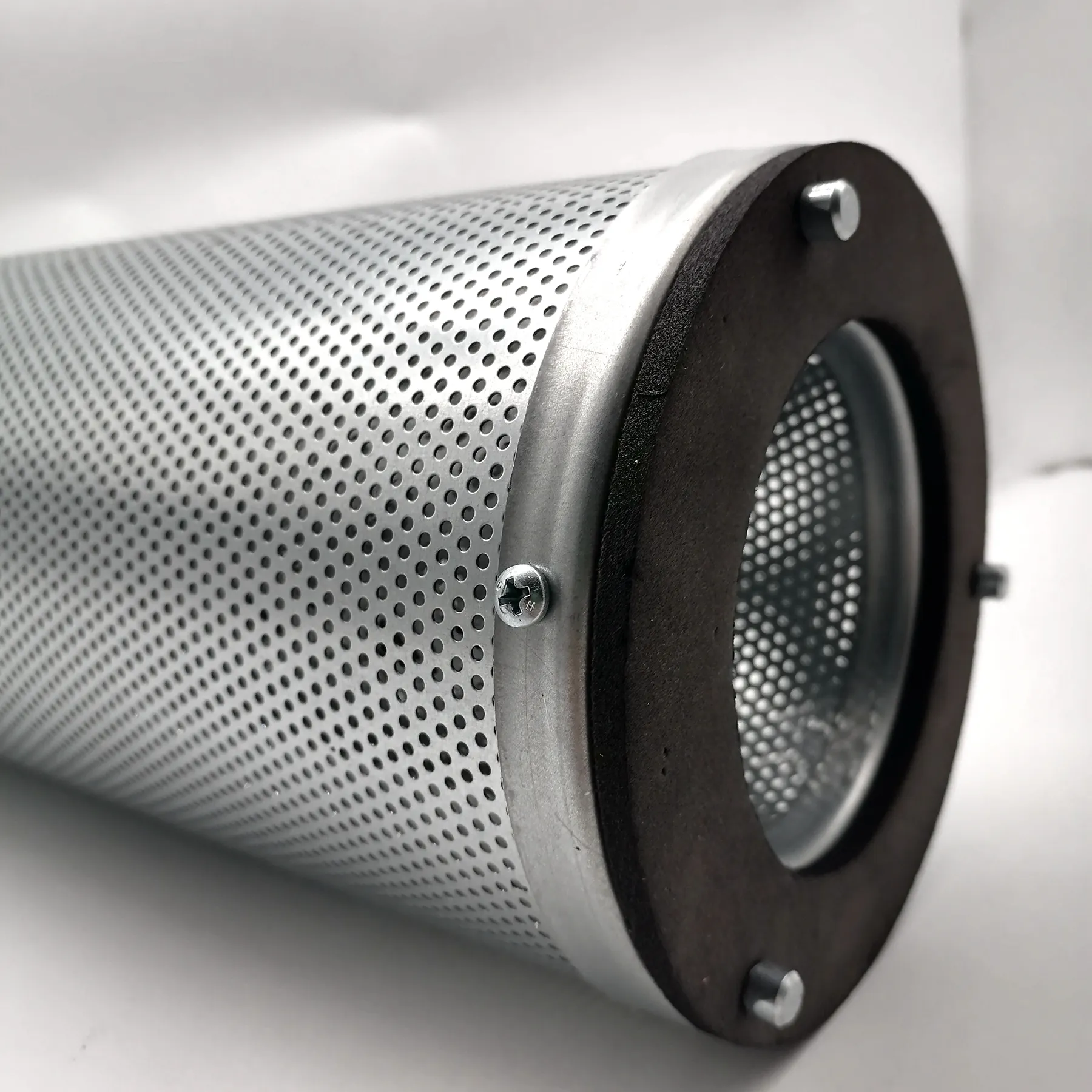

Air Filter High Performance Dust air compressor filter cartridge

Understanding the nuanced role of a high-performing filtration system in various industrial and domestic applications is crucial. Among these, the 100 micron stainless steel filter stands out due to its unique balance of precision and durability. This article delves into why this particular filter has become synonymous with efficiency and reliability, backed by real-world expertise and authoritative insights.

Authoritativeness in advocating for the use of such filters comes from empirical studies and certifications. Industry standards bodies and testing laboratories have rigorously evaluated these filters, further cementing users' trust in their performance metrics. Certifications from organizations such as ASME (American Society of Mechanical Engineers) or equivalent international bodies provide assurance of the filter’s compliance with stringent filtration standards. Trustworthiness is also significantly enhanced through consistent results reported by long-term users. Testimonials from seasoned professionals highlight reduced operational downtimes and increased process efficiencies as standout benefits. The filter’s role in safeguarding equipment from corrosive damage by eliminating abrasive particles helps in extending machinery lifespans, further enhancing trust in its utility. In addition to practical use cases and endorsements from industry experts, the 100-micron stainless steel filter's appeal lies in a growing body of research supporting its benefits. A study published in the Journal of Cleaner Production outlines the direct correlation between high-quality filtration systems like the 100-micron stainless steel filters and reduced environmental footprints of industrial processes. This connection bolsters the filter’s standing as a pivotal component in eco-conscious engineering practices. In conclusion, the 100-micron stainless steel filter exemplifies how innovation and durability can converge to meet dynamic industrial needs. By consistently delivering on its promises of efficiency and reliability, it upholds its status as a preferred choice among professionals dedicated to maintaining quality and enhancing productivity. As industries continue to evolve, the demand for filters that offer both precision and resilience will undoubtedly place the 100-micron stainless steel filter at the forefront of sustainable industrial solutions.

Authoritativeness in advocating for the use of such filters comes from empirical studies and certifications. Industry standards bodies and testing laboratories have rigorously evaluated these filters, further cementing users' trust in their performance metrics. Certifications from organizations such as ASME (American Society of Mechanical Engineers) or equivalent international bodies provide assurance of the filter’s compliance with stringent filtration standards. Trustworthiness is also significantly enhanced through consistent results reported by long-term users. Testimonials from seasoned professionals highlight reduced operational downtimes and increased process efficiencies as standout benefits. The filter’s role in safeguarding equipment from corrosive damage by eliminating abrasive particles helps in extending machinery lifespans, further enhancing trust in its utility. In addition to practical use cases and endorsements from industry experts, the 100-micron stainless steel filter's appeal lies in a growing body of research supporting its benefits. A study published in the Journal of Cleaner Production outlines the direct correlation between high-quality filtration systems like the 100-micron stainless steel filters and reduced environmental footprints of industrial processes. This connection bolsters the filter’s standing as a pivotal component in eco-conscious engineering practices. In conclusion, the 100-micron stainless steel filter exemplifies how innovation and durability can converge to meet dynamic industrial needs. By consistently delivering on its promises of efficiency and reliability, it upholds its status as a preferred choice among professionals dedicated to maintaining quality and enhancing productivity. As industries continue to evolve, the demand for filters that offer both precision and resilience will undoubtedly place the 100-micron stainless steel filter at the forefront of sustainable industrial solutions.

Latest news

-

How to choose a high-efficiency air filter? Here comes a professional guideNewsOct.21,2024

-

Air filter: multi-field application, protecting fresh airNewsOct.17,2024

-

Carbon air filter: a green guard to protect air qualityNewsOct.16,2024

-

Can activated carbon completely remove indoor odors and pollutants in air purification?NewsOct.14,2024

-

How to filter air efficiently and ensure indoor air quality?NewsOct.12,2024

-

Activated carbon filter: the invisible guard of clean water lifeNewsOct.11,2024

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: